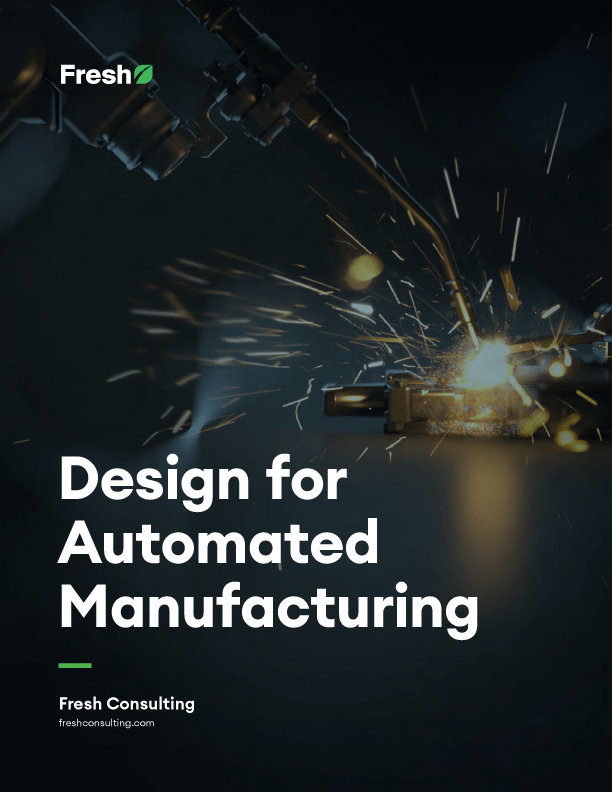

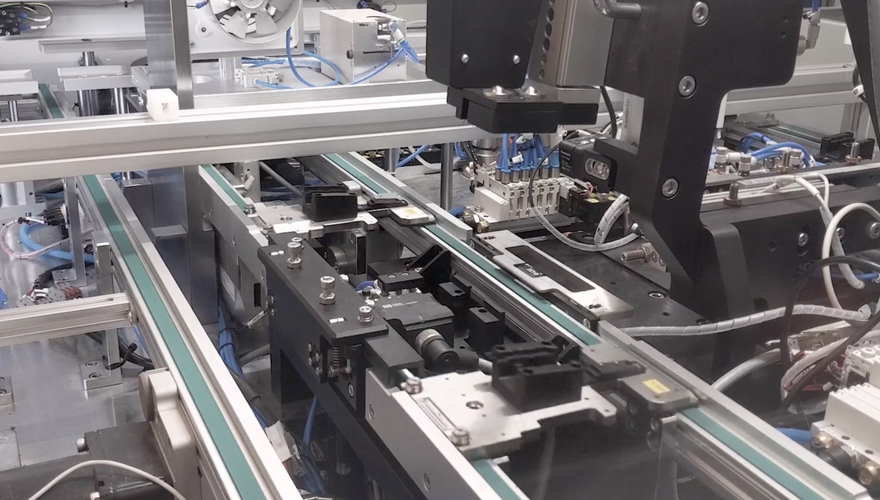

Hardware

Companies on the leading edge use intelligent machines to augment human labor and manufacturing operations, providing greater control and always-online production. Partner with us to reimagine your manufacturing environment, build advanced systems, maximize throughput, reduce waste, and increase precision in your business’s factory automation solutions. Create a plan for your business that will allow for cost savings in the long term while keeping you up to date on the ever-changing world of automation in the short term.

Get Started

Contact Us

Have a project?

Connect with our engineering team to discuss your challenge and how we can help.

Core competencies of our manufacturing automation solutions

- Resistance and laser welding

- Soldering and brazing

- Orbit forming

- Crimping and swaging

- Ultrasonic and RF Welding

- Laser mask welding

- Heat stake

- One and two part adhesives

- UV, visible light and thermal curing

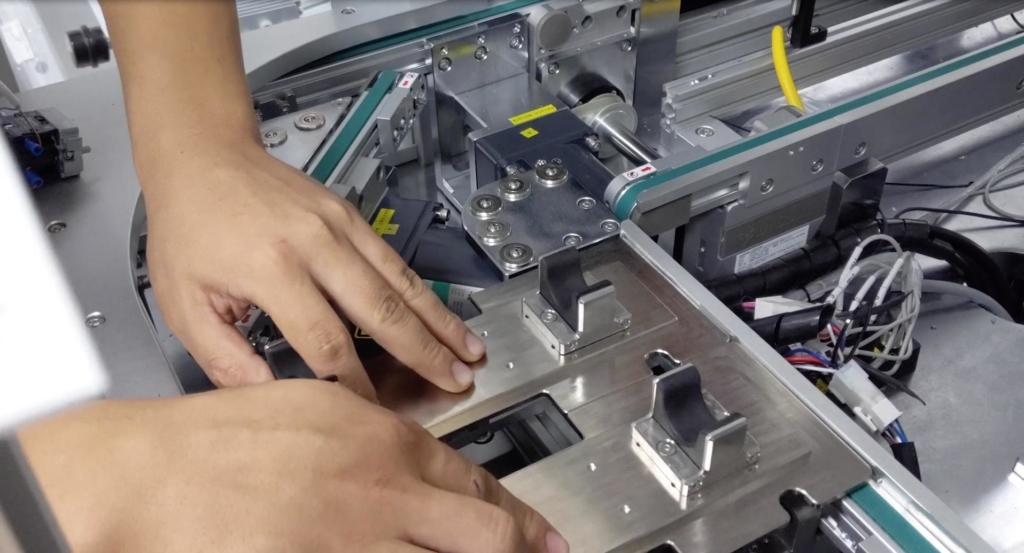

- Pick and place automation

- Vision guided precision servo placement to sub-micron resolution

- Industrial robot integration for flexible, multi-axis problems

- Precision dispensing

- Positive displacement pumps for repeatable dispensing of gels and precise volumetric dispensing of liquids

- Micro solenoid valves for high precision dispensing

- Ink jets for precise volumes

- Coordinated dispensing

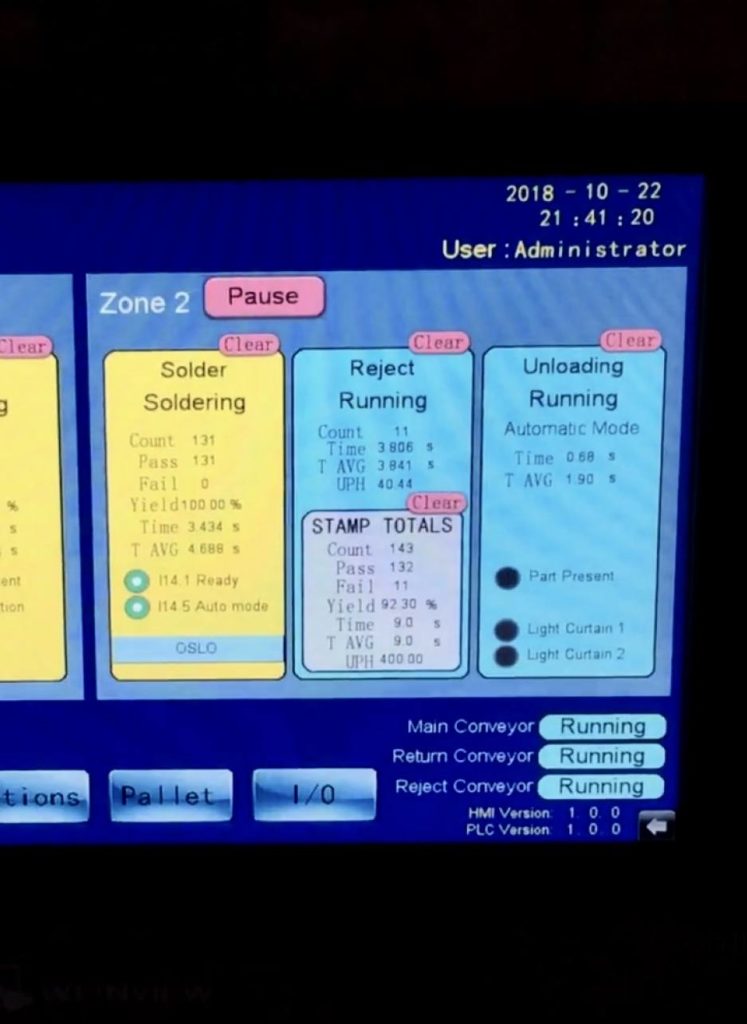

- PC control in C# or C++

- PLC control in all common industrial platforms

- GUI and SCADA development

- Factory host or MES/ERP communication interface over any protocol

- Material handling

- Power & free linear transfer systems

- Aspetic environmental control

- Inert environmental control

- Special temperature environmental control

- ESD control

- Etching and cleaning systems

- CMP

- Drying processes

- Belt, ball screw and linear motor motion stages

- Servo and stepper motors

- Rolling contact and air bearing stages

- Stand-alone controls to fully integrated, multi-axis motion controllers

- Vision guided motion

- Inspection of post placement accuracy

- Visible and IR

- Resolutions to sub-micron

- Optical power measurement for photonics products

- Vision inspection

- Electric & magnetic testing

- Voltage, current, hi-pot, magnetic flux, frequency

- Pressure decay leak testing

- Vacuum/trace gas detection

- Mass flow leak testing

- Industrial robot work cell

Drive efficiency in your automated manufacturing automation processes

The Fresh engineering team has the industry experience and cross-disciplinary technical background to create any solution you require.

Increase productivity: Increase throughput, decrease cycle times, reduce labor content, maximize utilization

Improve quality: Improve consistency, increase control, increase accuracy, drive continuous improvement

Reduce waste: Decrease mistakes, increase product precision, promote 100% inspection, streamline process flows

Delivering value tailored to an individual client’s needs, we help organizations keep up with the demands of the modern world and a rapidly evolving industry landscape.

A multi-disciplinary, end-to-end team

Customized Systems: Guided by a technology-agnostic approach, we partner with a wide array of other robotics and technology providers to build your customized system.

Scope & Reach: We have experience deploying systems overseas in countries like Taiwan, China, Indonesia, and Mexico. Our scalable workflows and partnerships allow us to handle projects of varying scopes.

Guaranteed ROI: The Fresh manufacturing automation team is made up of engineering and business experts who focus on understanding the challenges and requirements of each project. We follow a vetted consulting process to meet your technical and financial objectives.

Manufacturing automation partners for system scalability and innovation

Investing in change is risky without a solid understanding of the market and an iterative approach to innovation. Fresh views client engagements as ongoing strategic partnerships where, long after a solution is implemented, we continue helping companies mitigate risk and maximize opportunity.

- Align cross-functional teams to solve complex manufacturing problems

- Explore and validate your strategy with rapid prototyping and testing

- Reassess your approach as insights about the future of Industry 4.0 continue to emerge, with a strategic partner who can help you innovate and adapt

Intelligent, predictive manufacturing solutions

Based on where we’ve invested, we’re well-positioned to take advantage of the revolution in manufacturing IoT: integrating systems intelligently, using machine learning and AI to create predictive machines, and incorporating the power of the Cloud to gather real-time data.

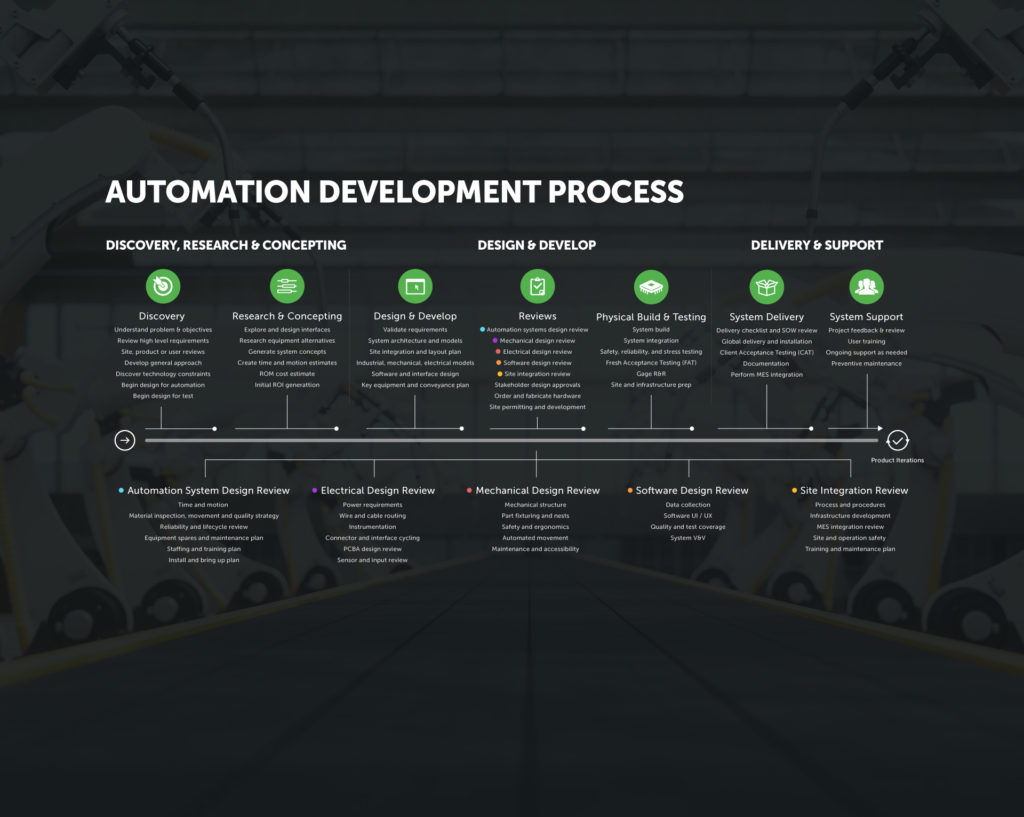

Our proven manufacturing automation process

Explore our approach to creating autonomous systems and machines that augment operations and workflows. We automate across a variety of use cases allowing your business to increase efficiency, maintain control, maximize throughput, and increase precision.

Related hardware capabilities

Explore our other engineering services, which allow our team to solve challenges for your organization and others, regardless of size, industry vertical, or product category.