Article

An Introduction to CFD and Its Real-World Applications

In electronics packaging, CFD (computational fluid dynamics) offers a pre-production look at thermal and heat management, allowing designers to optimize fan performances, board-level cooling, and lower enclosure surface temperatures.

In doing so, CFD enables fans to run quieter and, in some applications, converted into a fanless enclosure. These optimizations allow for uncompromised performance and increase the life of the end product, which has important implications for product development across various industries.

Throughout the rest of this introductory post on CFD, the first part of a series that explores the work we do at Fresh, we’ll cover:

- An overview of CFD and its role in mechanical engineering

- The primary benefits clients can expect

- Two examples of CFD work we’ve done at Fresh and can deliver for clients

The essential role of CFD in mechanical engineering

CFD enables engineers to virtually simulate the real-world environment their products must withstand. CFD simulation provides estimates of pressures, forces, and heat transfer due to the interaction of fluid flow around solid bodies.

Since this simulation happens virtually, engineers can avoid iterative, time-consuming model-making. Instead, once the CFD simulation is set up, an engineer can interpret the results, adjust the design, and re-run the simulation. The engineer can repeat these steps as often as needed to improve the design.

Although CFD analysis can be traced back to the 1920s, its use has been limited by its computational rigor. CFD began to be utilized in industry around the late 80s for the power generation sector. However, even then, it was limited by the computational technology available, and there were some mathematical issues to be improved upon.

Over the past 30 years, engineers have continued incorporating CFD into numerous applications. Current applications for CFD include thermal analysis of electronics packaging and batteries, eliminating cavitation in propellers, impellers and turbines, simulating aircraft aerodynamics to avoid turbulence, and optimizing heating venting and air conditioning (HVAC) systems in buildings.

The primary benefits of CFD

Above all, CFD provides an efficient, cost-effective approach to simulation.

Modern CFD software can handle complex 3D geometry with an approach that saves time, which is a valuable resource for the complexity of product development. Before CFD, the engineer had to choose between a combination of iterative model-making and hand calculations. Iterative model-making is both time-consuming and expensive, while relying on simplified hand calculations is overly conservative.

Although using physical models is recommended to verify the CFD results, CFD analysis is accurate; in many cases and verification can be done at the prototype stage.

Furthermore, results from the CFD simulation (such as forces, pressures, etc.) can be fed into FEA and additional simulation packages. This is helpful in many situations, such as designing an impeller for optimal flow (CFD) while ensuring it won’t structurally fail (FEA). CFD computations can be directly tied to mechanical loading for real-life stress evaluation using FEA (Finite Element Analysis).

Here is an example of how loads can be passed from SW Flow Simulation to SW Simulation for Finite Element Analysis (FEA):

Fresh CFD use cases: Cooling systems for PC fans and PCBs

Using CFD to simulate dissipated heat for electronic enclosures

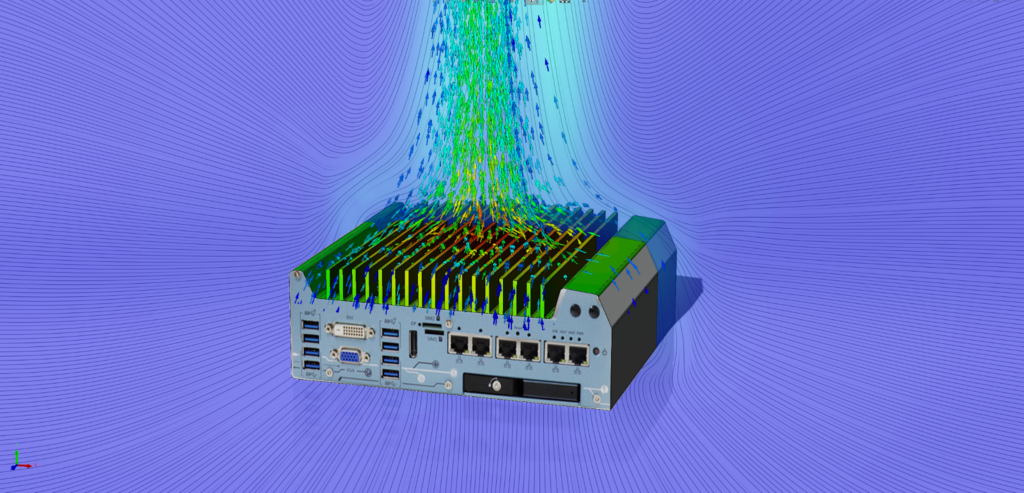

Our mechanical engineering team recently designed a fanless, ruggedized PC case using CFD to show free convection of computer-generated heat dissipating off of the PC Case’s fins.

This PC case is part of a larger simulation of a PC in a large enclosure used for the computation of SLAM (Simultaneous Localization and Mapping), a key element of our robotic software development practice. Because of the environment, it was advantageous to avoid a fan-cooled environment, and the engineer was able to simulate the heat generated by the components and increase the size of the enclosure to the point where overheating was not a concern.

Using CFD to analyze a concept and estimate performance

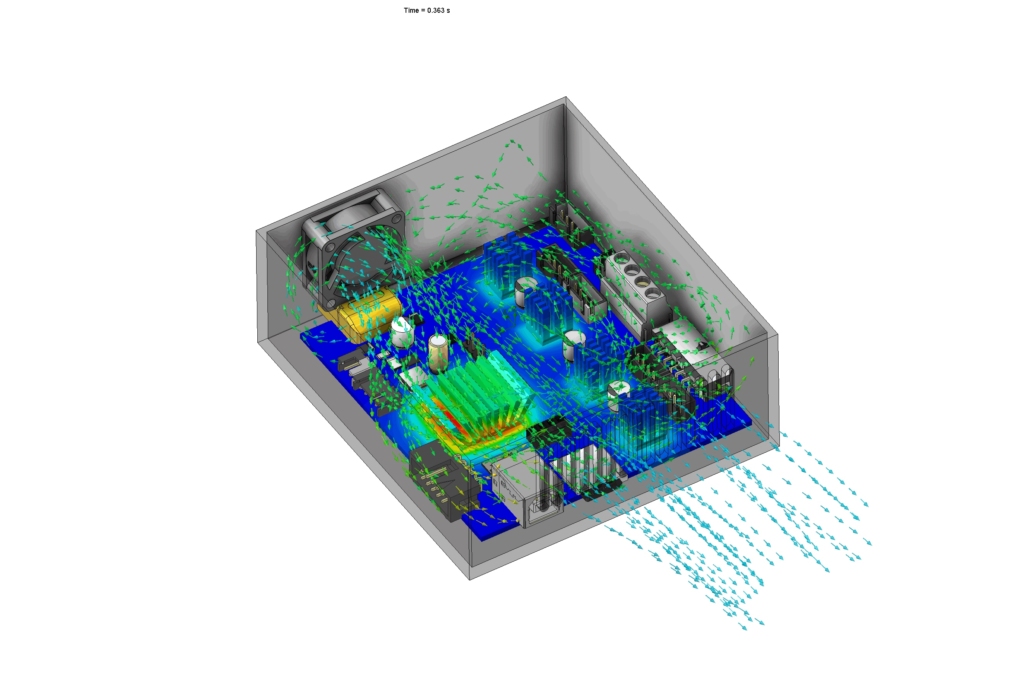

The graphic below shows a PCB jointly designed in Altium and SolidWorks using Altium CoDesigner, a simulation of a product engineered end-to-end by the Fresh team.

Before finalizing the PCB design, the fan could be sized and positioned to cool the electronics enclosure optimally. This included evaluating thermal pads, estimating the power budget, and eliminating heat pipes to reduce cost and assembly time.

With this optimized system, the product ran cooler and quieter, thus extending the life of electronic components.

Do you need assistance with CFD? Let’s connect.

At Fresh, we offer numerous engineering services including:

- CFD options as well as FEA, RF, and magnetic simulation

- An RF Lab as well as an ETL approved facility capable of fabricating UL508a and CSA control enclosures

- Rapid prototyping in a 10,000-square-foot shop with High Bays, offering quick-turn fabrication.

- End-to-end product design and fully-automated robotic work cells

These capabilities allow us to serve a wide range of clients in any industry vertical. If you’re working on anything related to these areas, or are simply interested in discussing the field, please reach out to us and let’s get started.

###

Additional Sources: Numerical Basis of CAD-Embedded CFD