Article

Partnering with University of Washington Students to Innovate on the Future of Robotics

In the fall of 2021, Fresh partnered with the senior class of Industrial Design students at the University of Washington to innovate on the future of robotics. Fresh posed the question, “How can robotics improve our standard of living?” Students were given four areas to ideate in:

- Elderly / Disability Aiding Robots

- Food Production & Food Service Robots

- Earth-centric / Ecology Focused Robots

- Emergency Services Focused Robots

Through an 11-week quarter, students researched their selected problem spaces, sketched, modeled, and prototyped their solutions, and finally presented their designs to Fresh. While students drove the creative production, Fresh’s industrial design team came in as consulting professionals, providing expert reviews and insights. Fresh industrial designers and mechanical engineers met with the students throughout the design process and provided feedback on user experience, mechanical considerations, and emerging technologies. The goal of this project was to tell a compelling story by bridging the gap between robots and humans with a creative design solution.

Collaboration with a focus on hands-on design

Having in-person critiques and designing hands-on is a crucial part of industrial design. Historically partnerships between the UW industrial design program and local companies have been in person, but our collaboration with UW ID required a more flexible, hybrid approach. Adhering to the guidelines for social distancing, we provided a tour of our industrial design shop, enabling students to observe how industrial designers work hands-on in the workplace.

One major goal of the quarter was to allow the students to physically build their prototypes, one aspect of industrial design that they have been prevented from doing with remote classes.

As such, building physical models was a new challenge for the students. Seeing their ability to hit the ground running was inspiring, and the results––which were owned 100% by the students––were impressive.

Featured work from the class of ‘22

The range of solutions that the class came up with was certainly inspiring. A few of the highlights from the Senior ID class are listed below.

Wilson Reavley’s “Jokull”

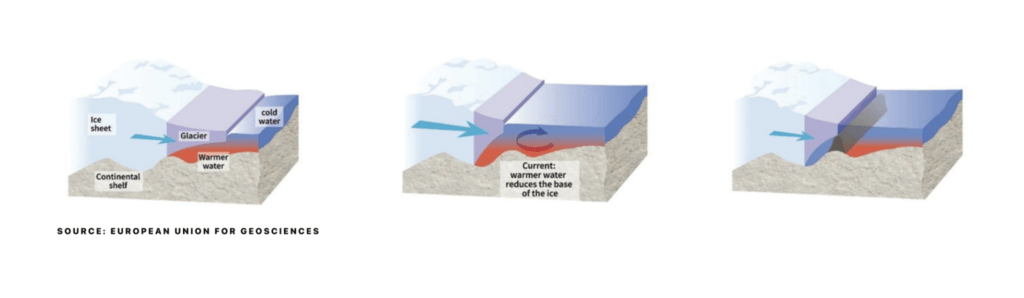

We were impressed by Wilson Reavley (LinkedIn | Portfolio), who ideated around the ever-pressing issue of environmental change. By constructing a wall of natural material beneath overhanging ice sheets, warm water can be blocked and the rate of glacial collapse can be significantly decreased.

To that end, Wilson designed Jokull, a robot that builds underwater walls in the harshest of conditions: the freezing waters in and around the world’s largest glaciers.

Gabe Port’s “Coho Sensor”

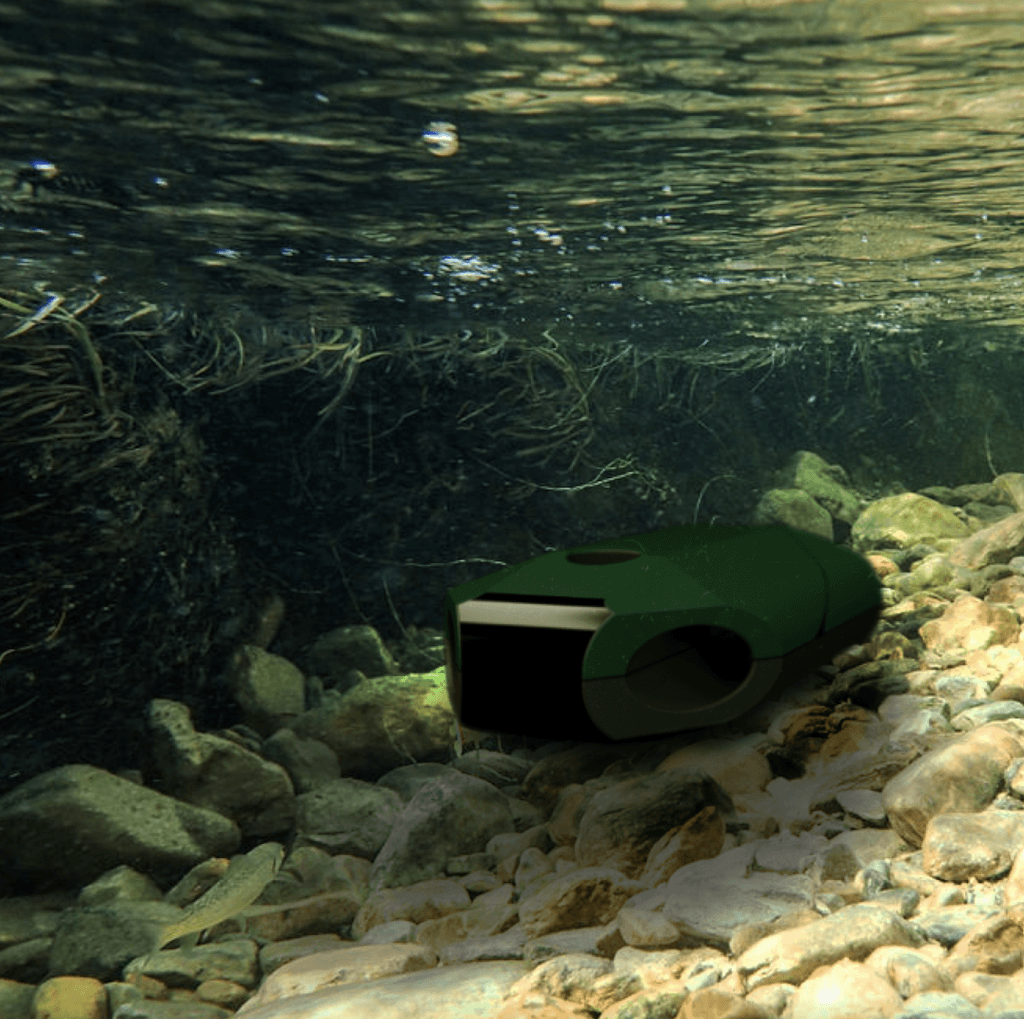

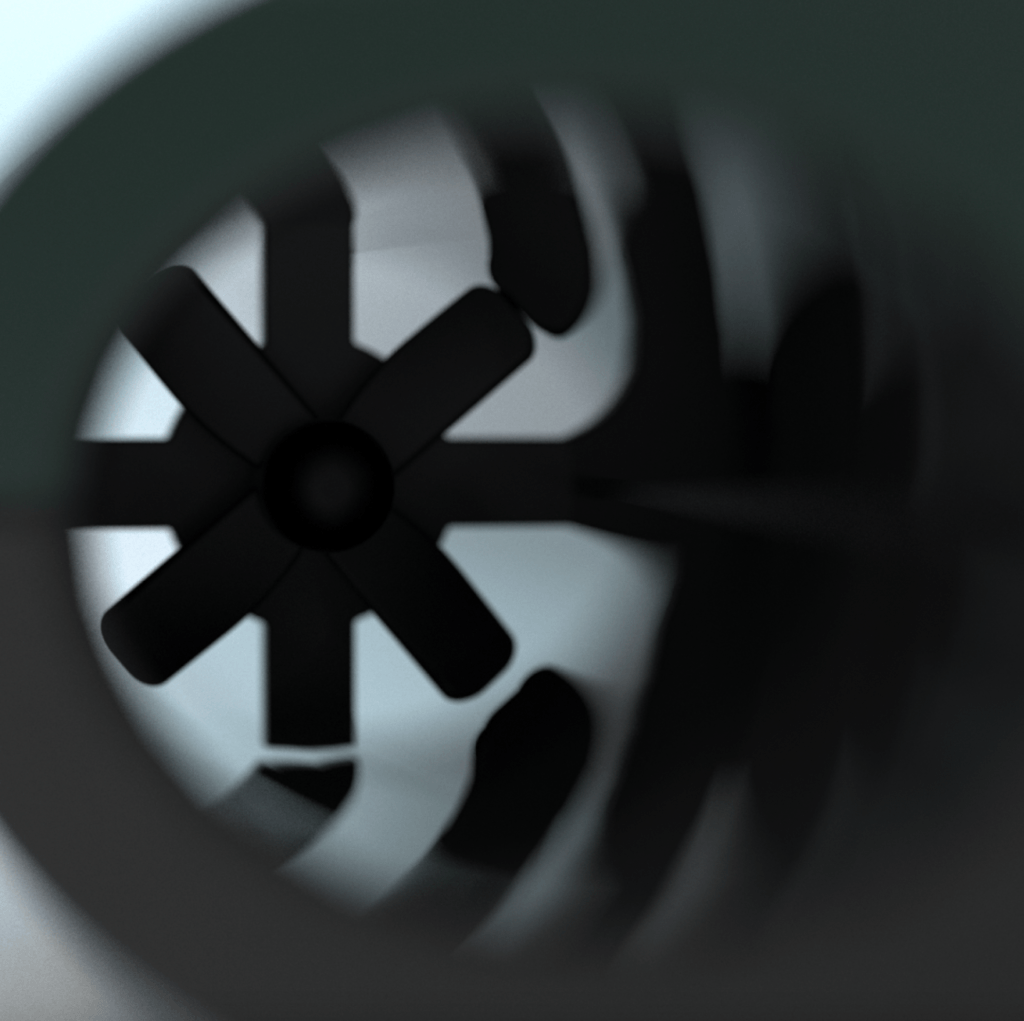

Another project of note that focused on Earth-centric robotics was Gabe Port’s Coho sensor (LinkedIn). Gabe designed an autonomous river sensing robot that minimizes human intervention in ecosystems, replaces invasive tagging methods, and records waterway health statistics.

The sonar sensor built into the front of the drone is used to scan the drone’s surroundings and map the riverbed for study. The drone has four propellers, two vertical and two horizontal, that respond to the information from the sonar system.

Grace Sturlaugson’s “AirAlert”

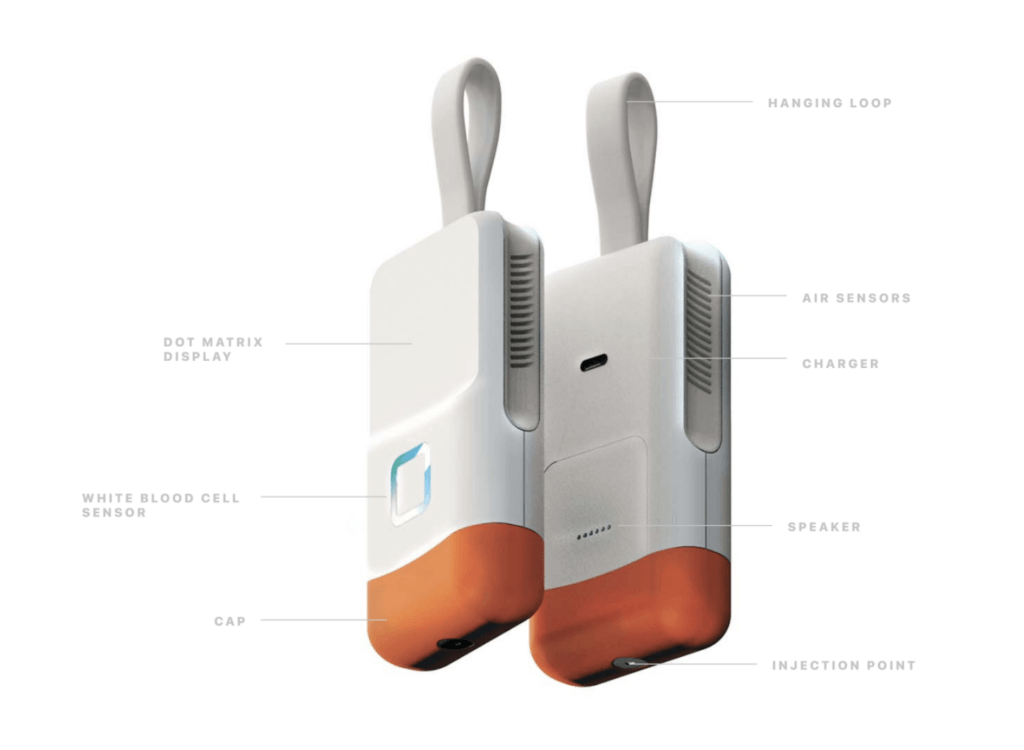

Grace Sturlaugson (LinkedIn | Portfolio) created AirAlert, an IoT device made to prevent severe allergic reactions.

AirAlert filters air and senses air particles, looking for harmful particles that could cause an allergic reaction. If a reaction is detected, AirAlert will prompt epinephrine to be delivered.

Aaron Jonghyun Park’s “A.P.R.O”

Aaron Jonghyun Park took a different approach to food and food services robotics than Grace. His research around food production and food service robotics led him to design A.P.R.O, the Automatic Pollinating Robotic Operator. This robotic arm assists farmers in the pollination and maintenance of their crops in controlled vertical farming environments.

This solution is unique from current vertical farming techniques that produce flowering crops such as tomatoes and strawberries using manual or bee pollination, which can be unreliable and time-consuming. A robotic system guarantees consistent and reliable pollinating 24 hours a day, 365 days a year.

What’s next?

Our purpose for writing this post is simple: these students, and the Industrial Design program at the University of Washington as a whole, deserve a major shout-out.

The seniors’ work speaks for itself, as does their character as individuals and ambitious young professionals. Despite weathering some tough circumstances during their education, these graduating Huskies exhibited perseverance and the types of qualities any organization should look for in prospective employees:

Tenacity, gumption, intrinsic-motivation, and the ability to collaborate and hone their craft, regardless of the hurdles in their way.

Suffice it to say that there’s a new talent pool in the Northwest. If you’re looking for young industrial designers with enormous potential, we highly recommend considering the 2022 University of Washington industrial design senior cohort.

If you’re interested in seeing more industrial design student work, we encourage you to attend the 2022 UW Design Show on June 8th, from 5-8 PM at the Jacob Lawrence Gallery.