Manufacturing Test System

High-Volume Automation and Testing

A test system to fine-tune medical devices for success in clinical trials

Background

Our international client had an innovative medical product concept in place. They came to us to build a high-volume testing system to help them prove the technology, pass clinical trials, and accelerate their go-to-market opportunity. Fresh engineers set out to create a system capable of testing hundreds of units per hour and gathering the technical measurements needed to validate the concept and pass FDA regulations.

Challenges

- Designing the system locally and deploying it overseas with our Asian manufacturing partner

- Building a laser measuring system to test vibrational and rotational forces, as well as usability in ideal and non-ideal environments

- System fabrication, integration, and ongoing support in light of geographical constraints, prioritizing the pinpoint accuracy needed to prove medical technology

Core Technologies

Accelerating medical device manufacturing

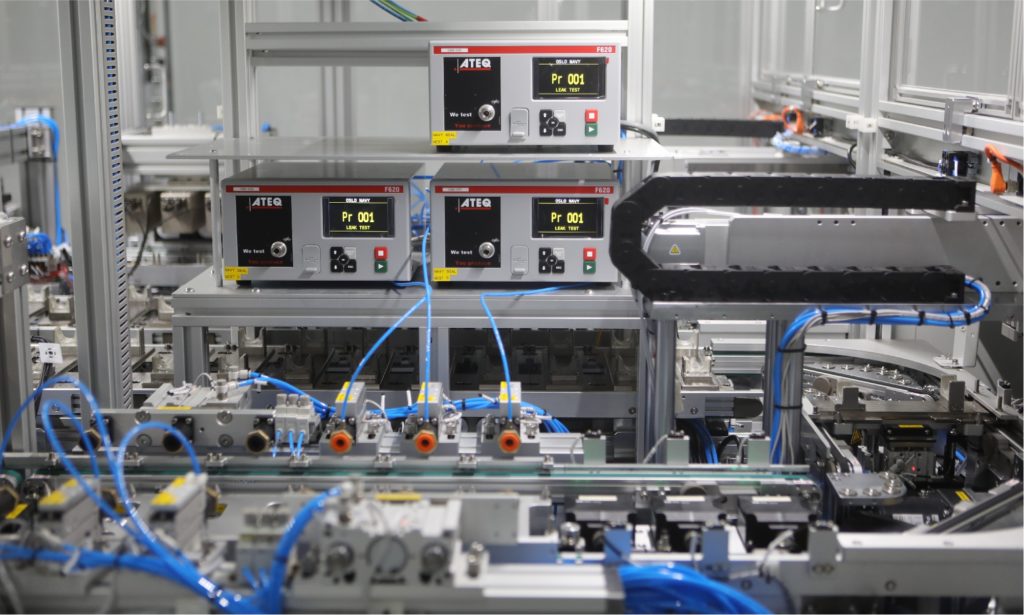

The high-volume test system vastly increased medical device testing capacity and significantly reduced manual labor, saving the client time and money. An automated, palletized conveyor system optimized throughput for our client, performing test and assembly tasks on 900 units per hour.

Technologies demonstrated

- High-Speed Laser Measurement

- NFC/RFID Testing

- BLE Testing

- Touch Sensor Testing

- IMU Testing

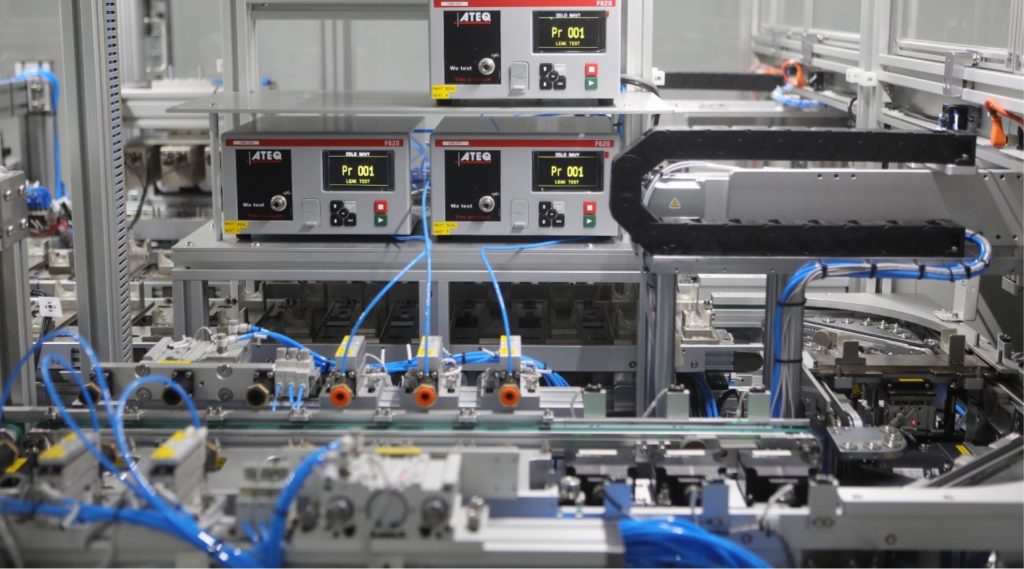

- Leak Testing

- Automated Soldering

- Sensor Calibration

- Product Configuration

- HMI and PLC Software

Maintaining speed, reducing costs, and ensuring clinical trial success

Rapid manufacturing was essential. But pinpoint accuracy for every unit is required in the medical field, specifically concerning clinical trials. The system had to be designed for fine-tuning individual devices, a potentially costly undertaking.

Thus, decreasing costs where possible was also essential. Balancing our experience deploying systems overseas, we created a workflow customized to the client’s unique needs that still addressed the pinpoint accuracy required for medical device development.