Services

From custom manipulators for precise handling to autonomous navigation systems for dynamic environments, Fresh Consulting delivers custom robotics solutions that enhance productivity, adapt to your infrastructure, and scale with your business.

Let's Connect

Custom Robotic Solutions for Your Unique Requirements

Fresh designs, engineers, and deploys integrated robotic systems tailored to your unique operational needs. As a robotics integrator, we combine off-the-shelf components as appropriate and engineer the remaining as custom elements to bridge gaps and optimize performance. The result is a finely tuned solution that fits your environment, processes, and long-term goals.

Key differentiators:

- Integration-focused approach, not one-size-fits-all products

- Seamless compatibility with existing infrastructure

- Scalable, future-ready robotic systems

Solve unique challenges when off-the-shelf won’t work

Custom robotics solutions overcome challenges where standard options fall short. Optimize performance for specific requirements, integrate solutions seamlessly into existing workflows, and adapt to specialized environments to deliver precision, efficiency, and lasting value.

Drive productivity, quality, and safety across workflows

Unlock greater productivity and safety with custom robotic system integration. Our solutions enable faster throughput, consistent quality, fewer errors, and continuous, round-the-clock performance, automating dull, dirty, and dangerous work to protect your team and drive measurable results.

Build scalable technology roadmaps for future-ready solutions

Fresh-built robotics solutions are designed with your technology roadmap in mind: delivering value today while paving the way for where you need to be in one, three, and five years. Our robotics solutions scale and adapt alongside your business, supporting incremental improvements that build lasting, long-term performance.

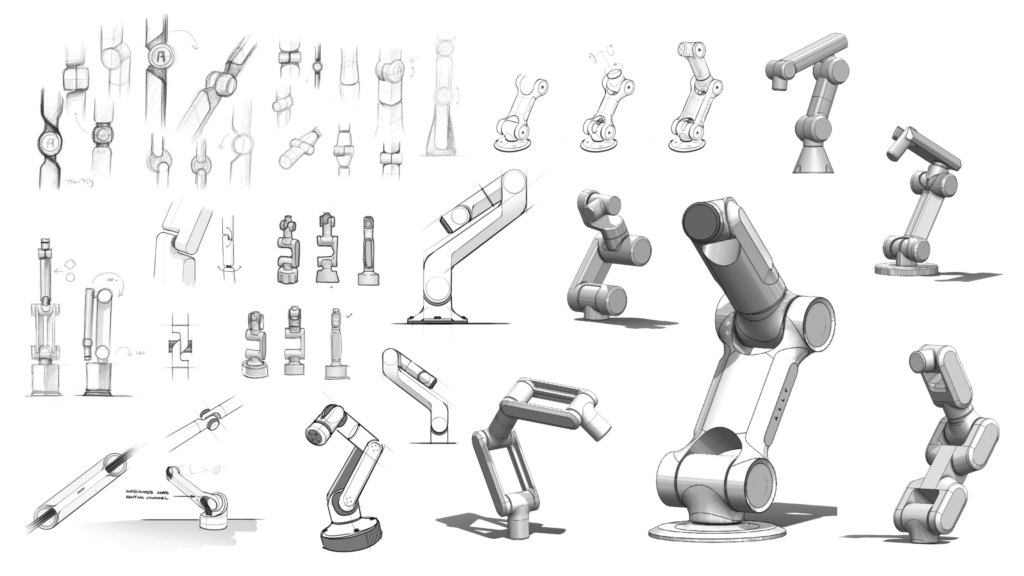

Advanced Manipulation

Our mobile robotics manipulation specialists design and build custom manipulators and actuators that enable precise object handling and task execution—such as welding automation, sanding, and assembly—in dynamic, challenging environments with diverse requirements.

- Custom manipulators: Task-specific design of robotic arms for unique requirements, enabling precise payload handling where standard arms fall short

- Custom actuators: Advanced force control, dynamic environmental interactions, and tailored performance for your specific application

- Mechanical engineering specialization: Mechanical engineering for precision kinematics, material optimization, and custom actuator integration, ensuring robust mobility, manipulation, and payload handling

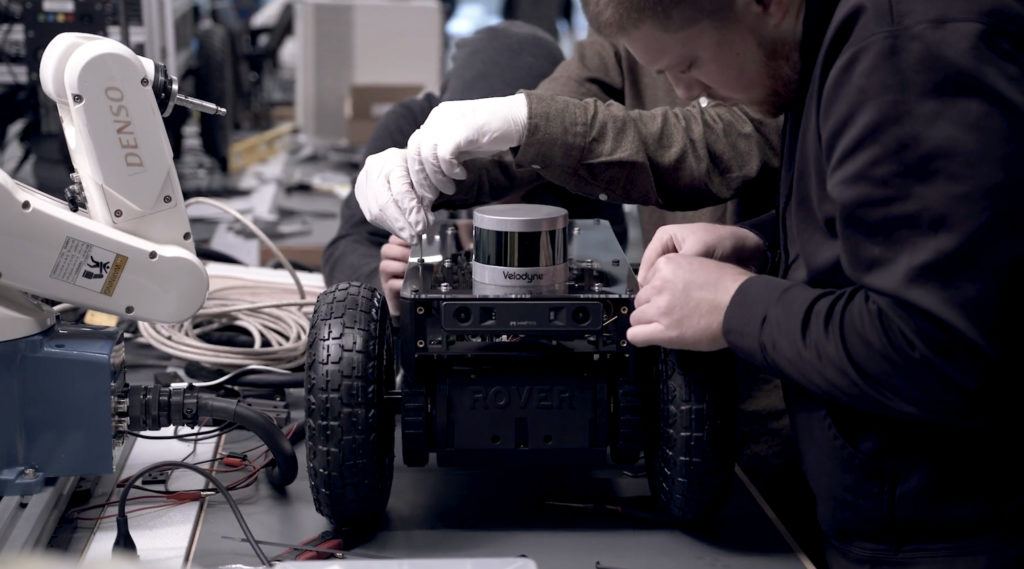

Mobile robotics development

Our autonomous navigation and integration specialists seamlessly incorporate advanced navigation and custom navigation stacks into your existing vehicles, equipment, and operational environments, enhancing or building upon off-the-shelf solutions.

- Existing vehicle and environment integration: Sensor fusion, AI algorithms, and custom interfaces optimized for your existing infrastructure without requiring complete replacement

- Custom solution development: Tailored navigation platforms, including modifications to off-the-shelf or bespoke nav stacks, to support specific vehicle types, mission requirements, and the unique challenges of your environment

- Building a roadmap for the future: Scalable technology roadmaps (sensor integration, safety systems, expanded autonomy) that prepare you for more advanced automation

End-to-End Custom Robot Development

As a true end-to-end robot integrator, we take ownership of the entire product development lifecycle—ideation, proof of concept, design, development, deployment, and beyond—combining engineering, software, and integration expertise to bring your automation vision to life with precision and continuity.

- Discovery to Design: Full requirements analysis, proof-of-concept validation, and custom mechanical, electrical, and software engineering tailored to your exact needs.

- Integration to Deployment: Existing infrastructure integration seamlessly connected with your equipment and workflows. Includes installation, commissioning, and hands-on team training.

- Optimization to Scale: As end-to-end robot integrators, we stay with you beyond launch, delivering ongoing support, system optimization, and capability expansion to evolve your solution as your business grows.

Advanced Hardware Integration

Having worked with a range of robotics technologies, we ensure every sensor, actuator, platform, and line of code is chosen for performance and precision. By selecting the optimal hardware for your environment and performance targets, we ensure optimal precision, efficiency, and longevity.

- Mobile Platforms & Manipulators: AMRs (automous mobile robots), AGVs (automated guided vehicles), and custom wheeled or tracked robots combined with tailored robotic arms, end effectors, and grippers for your exact payload requirements.

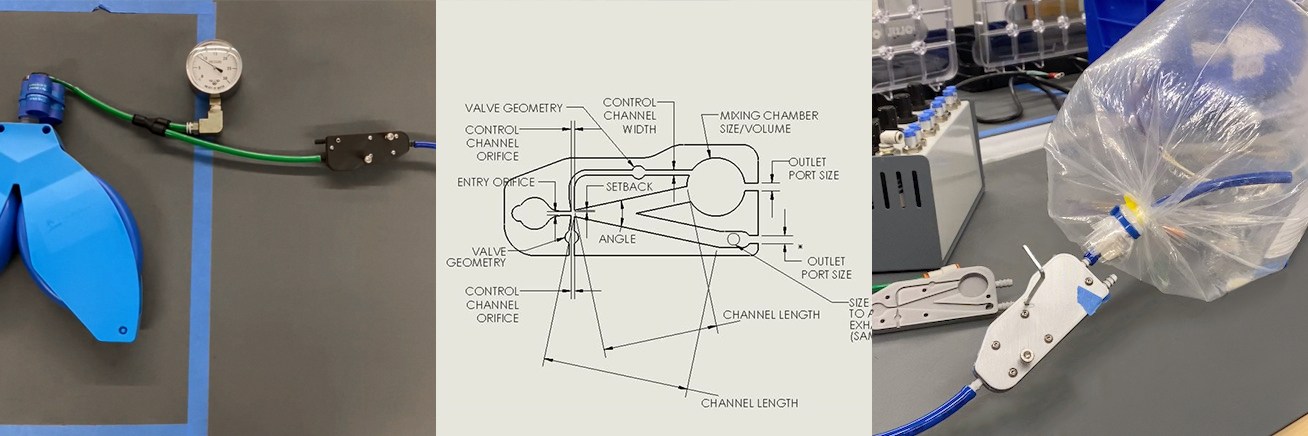

- Advanced Actuation Systems: Integration of electric, pneumatic, hydraulic, and smart actuators with force control and sensing for custom robots with responsive, real-world interaction.

- High-Performance Sensing: LiDAR, cameras, IMUs, force/torque, and tactile sensors delivering real-time environmental interaction, real-time perception, and feedback for robust automation.

Fully Integrated Robotic Systems

We deliver fully integrated robotic systems built around your operational goals.

- Tailored System Design: Custom integration across mobile robotics, manipulation, precision kinematics, and scalable architectures engineered for high-performance automation.

- Sensor Fusion & Autonomy: Advanced integration of LiDAR, vision, and navigation technologies with autonomous path planning, real-time processing, and intelligent decision making

- Seamless Infrastructure Integration: Technology aligned with your existing machinery, software, and workflows—future-ready and easily extensible as operations scale.

Software & Artificial Intelligence

Our robotics software stack merges proven frameworks with AI-driven intelligence to enable autonomy, adaptability, and integration across every layer of your system.

- Scalable Software Architecture: Frameworks built for reliable communication, rapid iteration, and enterprise scalability.

- AI & Perception: AI algorithms and machine learning models for real-time processing and decision-making, object detection, collision avoidance, navigation, SLAM, and advanced path planning with continual performance feedback loops.

- System Integration & Custom Interfaces: Custom middleware and APIs connecting robotics platforms to existing enterprise systems, creating unified control and data visibility across your operation.

Discovery & Requirements Analysis

- On-site operational assessment and data collection

- Workflow mapping and bottleneck identification

- Payload, precision, and throughput requirement analysis

- Environmental and existing infrastructure condition evaluation

- ROI modeling and feasibility assessments to validate the automation value of custom robots

System Design & Feasibility

- Component selection and performance modeling

- 3D system simulation and digital twin evaluation

- Mechanical, electrical, and software feasibility assessment

- Prototype validation of core functions and subsystems

- Cost, schedule, and risk assessment before build approval

Design & Pre-Deployment Testing

- Mechanical design for manipulators, kinematics, and frames

- Electrical design for power distribution, sensor fusion, and control systems

- Software development for autonomy, AI algorithms, and navigation logic

- Communication and custom interface architecture for system interactions

- Bench and subsystem testing for early performance verification

System Build & Validation

- Hardware assembly and subcomponent integration

- Software deployment and configuration of control systems

- Functional testing and calibration of all hardware subsystems

- Environmental simulation and endurance testing under load

- Full system validation for performance, safety, and compliance

Integration & Deployment

- On-site installation and infrastructure alignment

- Existing equipment integration

- Integration with networks and control systems

- Configuration of custom robots system interfaces and synchronization protocols

- Site acceptance testing and final performance verification

- Transition into production-ready operational mode

Training, Handoff & Support

- Operator and technician training for operation and upkeep

- Documentation and maintenance protocol delivery

- Remote monitoring and performance analytics setup

- Preventive maintenance and troubleshooting support

- Continuous optimization and system capability expansion as needs grow

Ready to Transform Your Operations with Custom Robotics Integration?

No matter your automation goal—whether it’s overcoming unique operational challenges, elevating your equipment with next-level autonomy and AI, or pushing the boundaries of what’s possible with advanced robotics—our team is ready to help.

Our robot integration specialists partner with you to validate your vision, assess feasibility, and design fully integrated solutions that deliver measurable impact, from advanced manipulation and mobile robotics to end-to-end automation and intelligent hardware-software integration.

Tell us about your project

Please provide us with initial information about your custom robotics project and we'll set up a discovery call to learn more.