High-Tech R&D

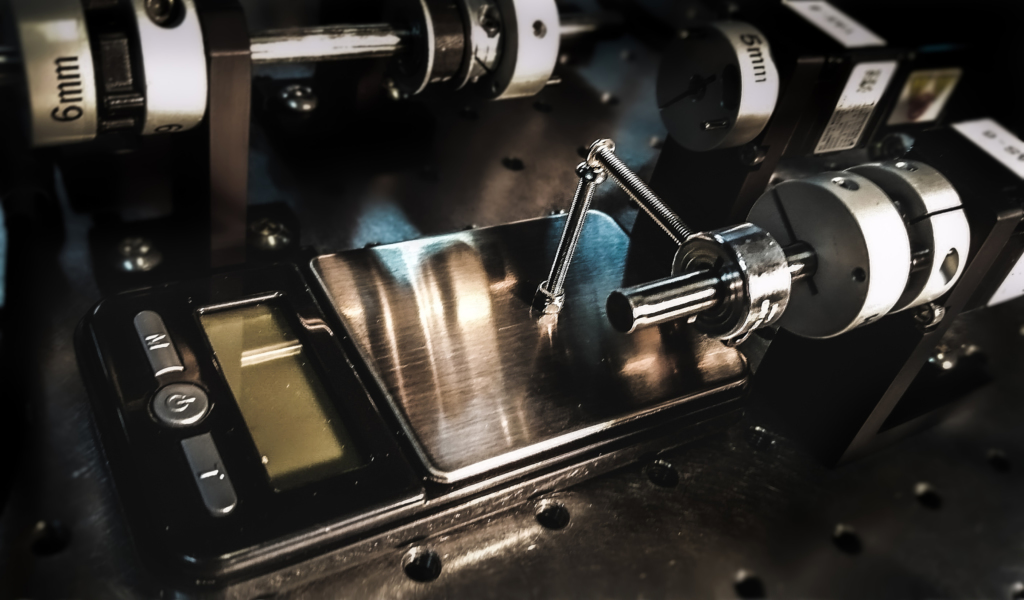

Physical Modeling System

We created a "sandbox" for engineers to experiment and prove complex kinematic models before development

Background

Our client, a prominent multinational technology conglomerate, needed a testing system for their cutting-edge research and product development work. Their goal was to create a consumer product that involved complex kinematic chains: coupled systems with interrelated, simultaneous movements like twisting, pushing, and pulling. Modeling complex physical processes is time-consuming and resource-intensive, so we set out to create a streamlined process for replicating and analyzing physical behavior.

Challenges

- Designing the system to run complex kinematic chains simultaneously

- Analyzing unique forces at different parts of the kinematic chain

- Equipping the system to measure simultaneous movements with extreme accuracy

Services & Capabilities

Breaking a kinematic chain into component parts

In the lab, there is room for trial and error. But as with any engineered product, our client’s final product had to behave reliably, as intended, in the real world. The lab was the perfect place for a system that replicates behaviors and gives engineers a better understanding of how they stack up. With the new system, our client was able to:

• Analyze the entirety of the existing kinematic chain

• Isolate and modify individual physical forces

• Experiment with changes, then reanalyze the chain in aggregate

Our system provided hands-on, tactile understanding and saved the client from additional trial-and-error later in the product development cycle.

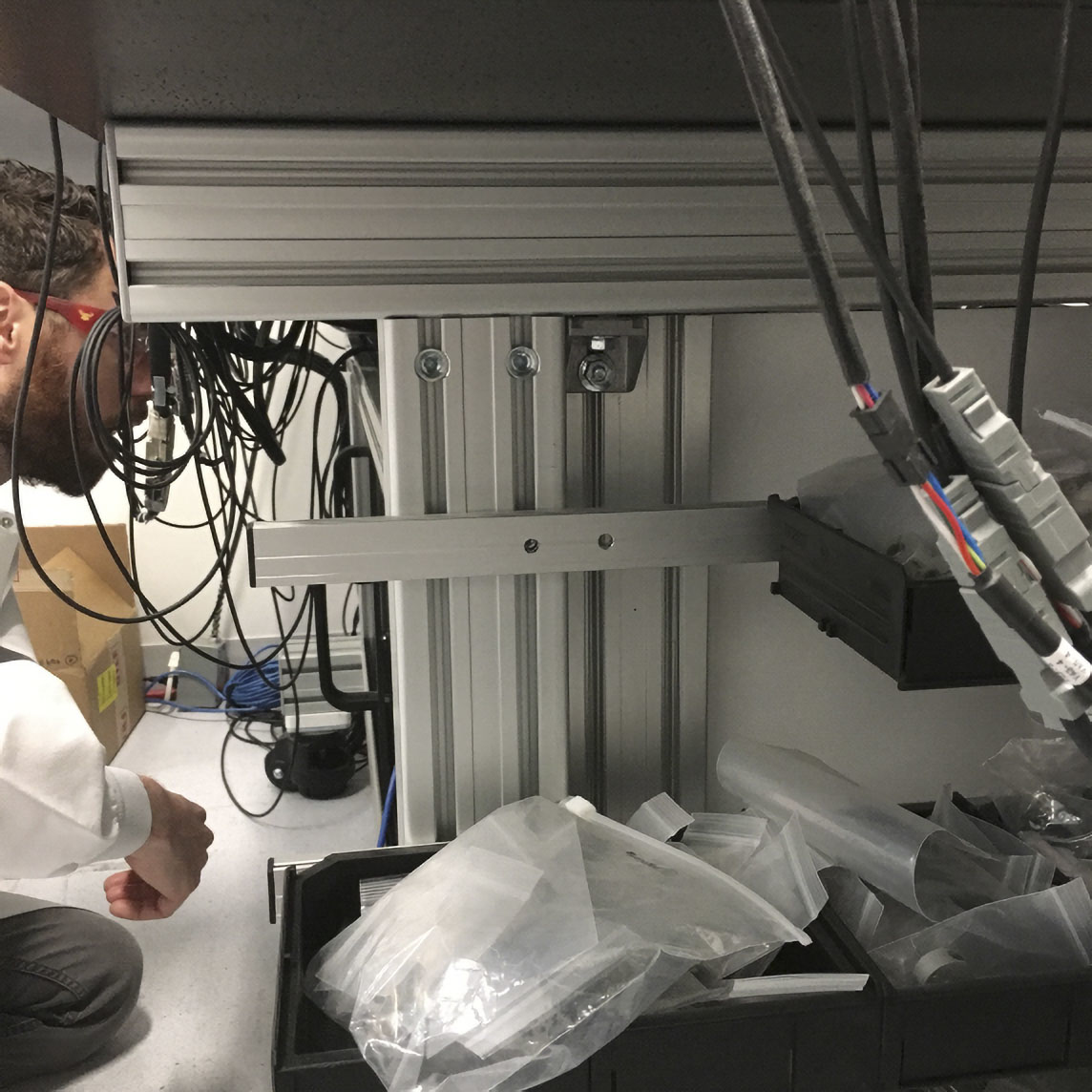

A scalable, multi-purpose solution

The math must be accurate for any product with a complex kinematic chain. While our client’s use case was specific, other industries can benefit from this type of tool:

• Robotic systems with arms, legs, and manipulators

• Autonomous vehicles with complex steering systems

• Wearables and prosthetics for human users

We equipped the client to test various scenarios, but the system is also the foundation for additional work.

Technical output

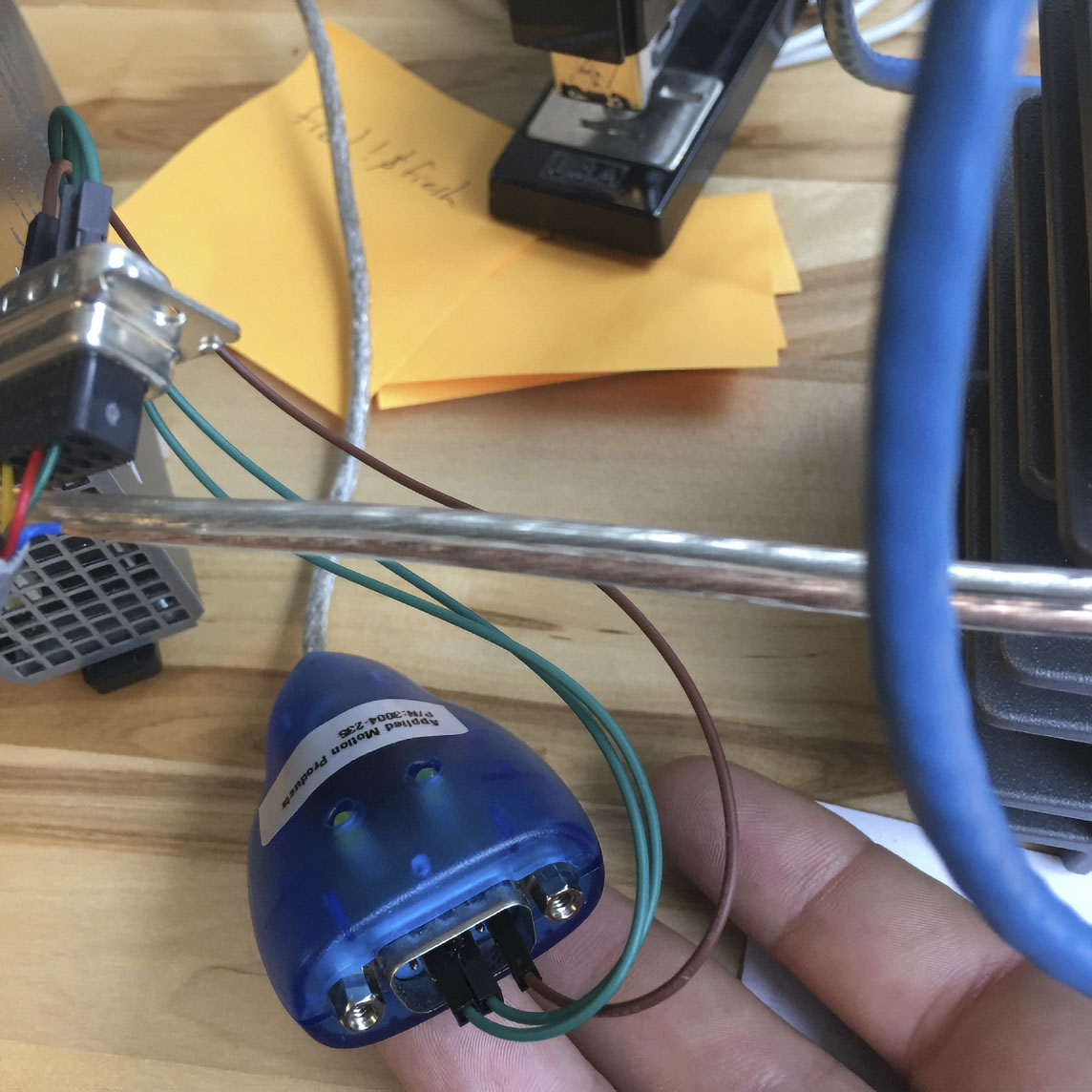

• Python test scripting in a LabVIEW environment.

• Integrated hydraulic, pneumatic, and electromechanical systems.

• Firmware development.

• Simultaneous control and precision measurement of cross-coupled actuators.

10Nm

Unprecedented low-level precision, capable of going up to 5-10 newton meters