Article

Introducing Worldwide Ventilator: An Open Source Emergency Ventilator Prototype

The Problem: Not enough ventilators at a time of global crisis

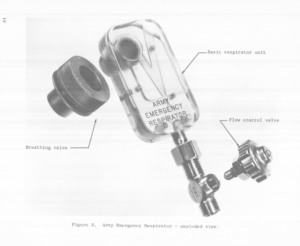

As part of our COVID-19 response, we decided to look at ways that our engineering team might be able to contribute to the shortage of ventilators. We discovered a design from a 1968 US Army field manual for a mechanical ventilator and asked ourselves what it might look like to update that design to modern day specs and manufacture.

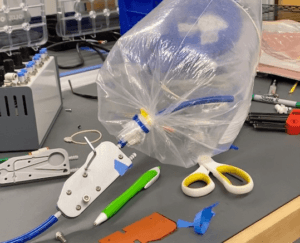

Chief Science Officer Emeritus Jeff Alexander brought together several members of our team, from mechanical engineering to industrial design. Over the course of a weekend, we built several prototypes and tested them out on a 3D printer, using commercially-available parts such as an air compressor and a bag valve.

Chief Science Officer Emeritus Jeff Alexander brought together several members of our team, from mechanical engineering to industrial design. Over the course of a weekend, we built several prototypes and tested them out on a 3D printer, using commercially-available parts such as an air compressor and a bag valve.

In parallel, we began a project website, Worldwide Ventilator, to function both as our external call for collaboration as well as a place to journal our progress each day.

Why now?

At Fresh, we believe in designing innovative products that solve real world problems. We also realize sometimes the problems to solve are right in front of us, and rather than wait for someone to ask us to do something, we have the resources as well as an obligation to our communities to step up to help. We could not sit idle as our community in the Pacific Northwest, and the broader country, was impacted by the coronavirus pandemic.

A number of things also changed around us that accelerated the design process. First, many in the maker community began putting out calls for PPE, either through additive manufacturing or through old-fashioned sewing machines. Others were also inspired by the same Army field ventilator.

From a regulatory perspective, the US FDA issued new guidance on accelerated pathways to obtain an Emergency Use Authorization (EUA) waiver for certification, which would allow consultancies such as ours to participate in the design and development of medical equipment.

Why Fresh?

Fresh is composed of multidisciplinary designers, strategists, and engineers who solve problems of this complexity for our clients. We realized the tools and expertise that we bring to bear for our clients could be used to solve this problem in front of us. We could get started on something and share it quickly for the community to respond.

From there, we quickly realized there was interest from both the scientific community and potential customers around the world. Our team connected with volunteers all around the world, reached out to organizations in Oregon, Washington, and Massachusetts to learn more about the process for testing a medical device and incorporating feedback into our product design.

How it works

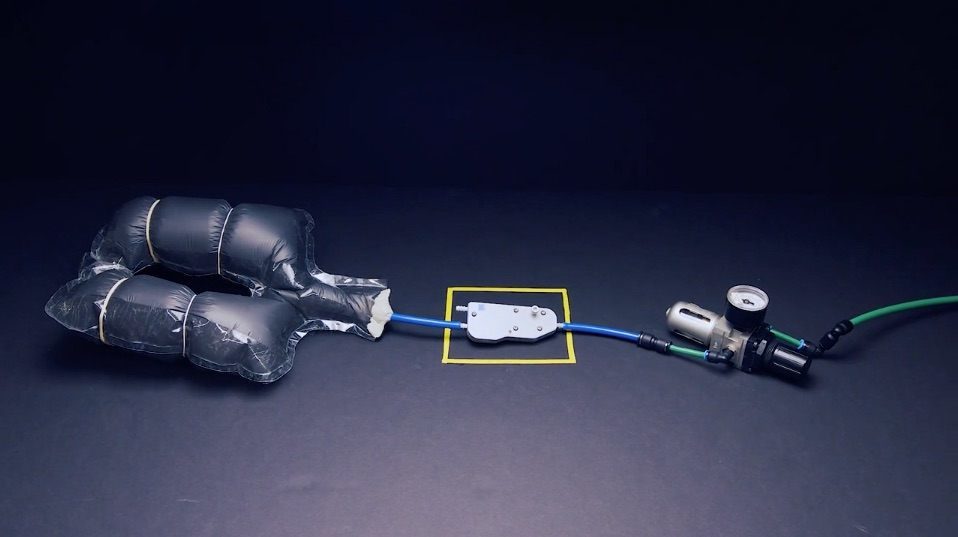

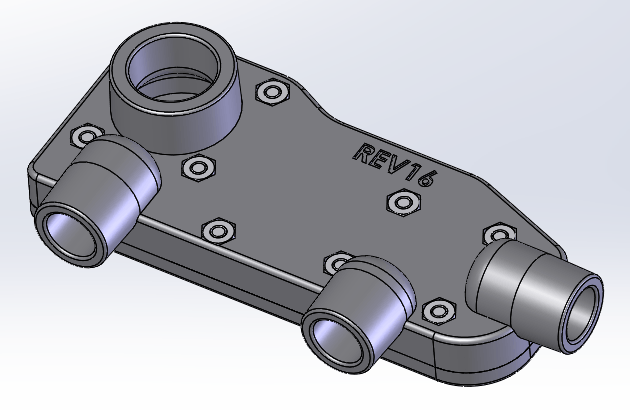

Our device is an automatic assisted breathing device that uses pressure to switch modes. It responds well to both assisted and automatic breathing. It can do more or less based on a patient’s own capabilities. If a patient tries to inhale, then it will help them inhale. If a patient tries to exhale, then it will help them exhale. Pressure builds on both sides of the bistable fluidic amplifier to determine when to switch, so when the lungs fill up, the device switches to the other side and helps exhale. And when lungs get too low, it switches to the other side and helps inhale, while keeping a positive pressure throughout. Three knobs on the device set the inhale pressure, the exhale pressure, and the duration of the exhale volume.

This project is open source, Creative Commons Attribution Noncommercial 4.0. Source files can be downloaded here. The rest of the ventilator system relies upon commercially available parts, including a tight face mask, vinyl tubing, an air compressor, and a sanitation filter. Oxygen and a nebulizer can also be added, similar to how they would be added to a normal ventilator. The anticipated bill of materials cost for the product is less than $10 in low volume.

The team plans on eventually selling some of the devices or kits through the Worldwide Ventilator site.

Building traction

We’ve seen some incredible traction and feedback over the first few weeks of this project. Part of this is due to our rapid prototyping and iterative feedback process, and showing our work. We quickly went from a functional 3D-printed prototype to one that could undergo computational fluid dynamics testing from scientific experts.

Some highlights from the first few weeks:

- Project website set up in ~72 hours

- Set up a demo with an inflatable bag for video to show progress

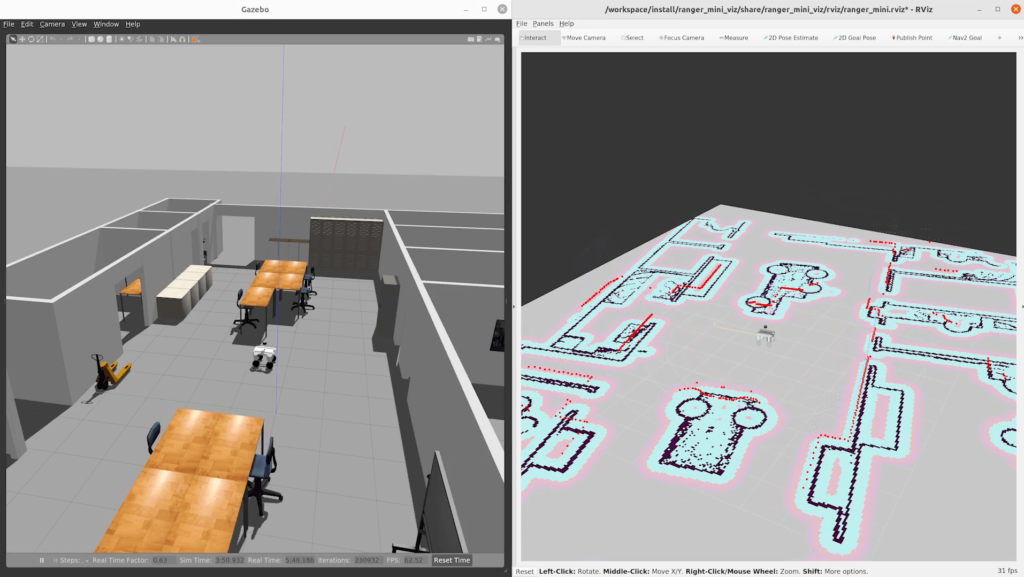

- Kicked off the process of CFD (computational fluid dynamic) analysis for our ventilator to find which variables have the greatest effect in the operation of the device

- Connected with a team of CFD volunteers through Stanford (SU2 code open source community) and other individuals from companies like Amazon

- Held conference calls with ZIAN and MUSC for collaboration

- Currently on our 16th iteration of the product design!

- Meeting with the CFD team, made up of people from the US, Germany, Italy, Israel, England, Scotland, and Netherlands

While the progress has been healthy, we recognize that the product isn’t likely to be complete and in market fast enough to address the immediate needs of US patients. We hope it can be part of a second-wave response, or to support patients in other countries around the world who might need a more affordable option. We continue to iterate to improve upon the design, and are looking forward to a day where a version of this product could be used to help someone combat COVID-19.

Our ask of you

If you’re a medical device expert, a potential customer, or a collaborator, we want to hear from you. Interested parties can reach out using this form. And if you have feedback or just an intro that you’d like to make, please let us know.