Podcast

The Future Of Batteries

This episode explores the future of battery technology with Rick Costantino, focusing on Group 14 Technologies‘ silicon-based anode innovation. Rick provides an in-depth look at advancements driving lighter, higher-capacity, and faster-charging batteries, and details the company’s global manufacturing growth and commercial impact. He discusses collaboration across the battery supply chain and the transformative effect of enhanced energy storage for consumer electronics, electric vehicles, and industrial applications. Rick also emphasizes the role of innovation, flexibility, and sustainability as batteries become foundational to next-generation technologies.

Podcast Transcript:

Jeff Dance: In this episode of The Future Of, we’re joined by Rick Costantino, CTO and co-founder of Group 14 Technologies, to discuss the future of batteries. Thanks for being here with us, Rick.

Rick Costantino: Thank you, Jeff. It’s great to be here.

Jeff Dance: I’m going to do a quick intro of Rick. As I mentioned, he’s the CTO and co-founder of Group 14 Technologies. They’re actually the world’s leading commercial manufacturer and supplier of advanced silicon battery technology for consumer electronics, electric vehicles, and more. Rick himself has 30 years of experience in product development across the chemical and biopharmaceutical industries. He holds more than 90 U.S. patents and has over 50 publications. I’ll have to ask you what you do for fun, but that’s amazing. He also has a PhD in chemical engineering from MIT and bachelor’s and master’s degrees in chemical engineering from Johns Hopkins University. So, we definitely have the right guy on this podcast episode.

Rick Costantino: It’s actually a little outdated. It’s 90 patents now.

Jeff Dance: Tell us a bit more about Group 14. For many people listening to the podcast, if they’re deep into batteries, they probably know about you guys. But for those who don’t, give us a bit more information about Group 14.

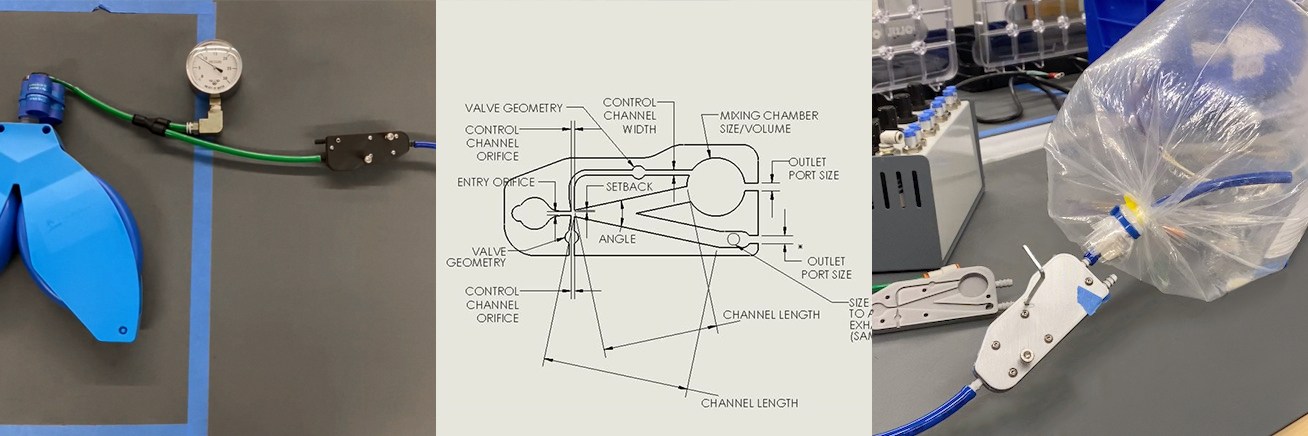

Rick Costantino: Sure. At Group 14, we’re on a mission to electrify everything. Our role in that process is making the world’s most advanced anode material. For the last 50 years, lithium-ion batteries have been using pretty much the same anode, which is graphite. Now we’ve developed a product called SCC55, a silicon-based anode material, which allows you to store up to 50% more energy in your battery. That means batteries can be lighter and smaller, and you can charge and discharge them at much higher rates—an order of magnitude faster than a standard battery. This enables a lot of other battery technologies and end-user products. The analogy I like to use is we’re sort of the “Intel inside” of the battery world. We don’t make the battery, but we make the materials that make batteries better.

Jeff Dance: Tell us more about the fundraising. I heard you’ve raised an impressive amount.

Rick Costantino: Yes, we’ve raised several rounds. Our last round, Series D, was $463 million, I believe. With that, we purchased what was previously a joint venture with SK in Korea. We now own that manufacturing facility, so we’re one integrated global company. We have our plant in Korea, two plants we’re building in the Pacific Northwest in Moses Lake, Washington, and a silane factory in Schwarzheide, Germany. So, we have multiple locations worldwide.

Jeff Dance: Just the locations alone—Korea, Germany, and you’re headquartered in Seattle, Woodinville, right? It seems like you’re setting up well to be one of the biggest future battery material providers. That’s awesome. And your investors—tell us about some of the key names. It seemed like there were some big players supporting this transformation.

Rick Costantino: Sure. We spun out from another company called Energy2, which was acquired by BASF, the world’s largest chemical company. So, they were sort of our first investor. We also had a Department of Energy project for $4 million. That’s how we started, with very humble beginnings a decade ago. We’ve raised several rounds since then. Our early round was led by ATL, one of the world’s biggest battery makers in terms of number of batteries. We had many partners up and down the battery supply chain—companies like Cabot and others in the battery space. That gave us good validation and allowed us to develop our product in concert with suppliers, customers, and sidestream partners—other folks involved in battery components. We were very focused on collaborating and getting investment from those in our space, rather than just venture capital. Our Series C was a flagship round led by Porsche, which gave us validation from an automotive OEM. We’ve been fortunate to do these great rounds, even when times are up or down, showing how important this battery space is and how dedicated we are to making silicon batteries. The performance is now so advanced that they’re being called silicon batteries instead of lithium-ion batteries to differentiate the performance.

Jeff Dance: Interesting. Before we dive in, you mentioned 90 patents. What do you do for fun?

Rick Costantino: For fun, I like to ski. I saw you were a snowboard instructor at Park City in your bio, and I love to ski there—it’s a great place. The Northwest is fantastic for outdoor activities—hiking, mountain biking, and downhill skiing is probably my favorite.

Jeff Dance: That’s awesome. So, you mentioned SCC55. Is that already on the market? Are there devices using the material, or are we still waiting for mass production?

Rick Costantino: We are in mass production. Our product is in millions of batteries for cell phones around the world. For example, through ATL, it’s in the Honor phone—an AI-enabled phone. Having our material in that battery allows those phones to do more than before. We have over 100 customers right now. Some of them are already on the market, and others will be soon. I can’t name them all, but, for example, some are in electric aviation. The Archer Midnight Air Taxi, which will be the official air taxi for the 2028 Olympics in LA, uses our material. I’m hoping I can get a ride on that—let me know if you want me to save you a seat.

Jeff Dance: Please.

Rick Costantino: I always joke that when the first electronic heli-ski company starts up, I want to be on the first trip—maybe not the second trip, but definitely the first.

Jeff Dance: I’m a big heli-skier, so we should talk about that at lunch.

Rick Costantino: Absolutely, I’d love to talk about it. So, yes, we’re in a lot of products now, and a lot more are in the queue. Some markets move faster than others. Consumer electronics move very fast, while automotive takes longer to get into products.

Jeff Dance: So you’re in millions of devices, but if we look at the overall battery market, are we just scratching the surface? Is most of the battery market still using graphite? Are we at the tipping point, or just the beginning of a new wave?

Rick Costantino: We are definitely at the tipping point. We’re now in the Silicon Age. Silicon transformed the way we store information, and now it’s transforming the way we store energy. It’s a huge transformation. I’m always amazed at what our customers can do once you give them more performance. I’ll give you an anecdote: Early on, when we were just a handful of employees, my CEO and I visited a very large consumer electronics customer. We were nervous, not knowing what to expect. But when we arrived, there were about 20 engineers excited to meet us, telling us how our material was allowing batteries to do so much more. They could pack more into devices and imagine new things they couldn’t before. That was a huge moment for me, realizing we needed to step up our game and play our part in this exciting ecosystem.

Jeff Dance: Give us some more specifics. I want to talk about consumer electronics and EVs. You mentioned lighter, smaller, longer-lasting, and more powerful batteries—these are huge for the market. Can you quantify some of those benefits?

Rick Costantino: Sure. We have customers who have demonstrated a 50% increase in energy density. That means you can make your battery 50% smaller or pack 50% more energy in the same space or mass. That also means a battery can be 50% lighter. For example, lighter batteries enable the whole business model of electric aviation. Some customers have told me that our material enables their business model. If you can make batteries smaller, you can put them anywhere—medical devices, glasses, and more. These things are happening now, and even more is possible. AI is also turning out to be a huge market. The CEO of ATL said this market might be bigger than automotive. The rate at which these batteries can deliver energy and switch between high and low rates is fundamentally important for AI. One customer had a battery that could switch from high to low energy delivery every half a second—graphite can’t even do that once, but silicon can. They had to update their equipment to keep up, and now they’re switching at microseconds—six orders of magnitude improvement. Apparently, this ability is important for the AI learning phase, making batteries a key enabler for AI.

Jeff Dance: AI on the edge is super important, and often relies on battery power. I can see that. We’re working on robotics right now, and a lot of people don’t realize the next wave—the physical wave of AI—where AI is embedded in all the things around us. That’s really exciting. So, six orders of magnitude more speed and transfer, a 50% jump in energy density, and lighter batteries. Is that because you need less volume to store the same amount of energy?

Rick Costantino: Exactly. To explain the material a bit: Graphite is a great material, and it’s part of the group 14 elements, my favorite column on the periodic table. These elements have four electrons in their valence shell, allowing them to form bonds. Carbon, in the form of graphite, forms sheets, and lithium intercalates between those sheets in the anode. It’s very stable and can go for thousands of cycles with little capacity loss. Silicon is different. Lithium forms an alloy with silicon, and this process is much faster. Silicon can store ten times the lithium compared to carbon. The challenge is that silicon expands and contracts during cycling, which can break up the material and degrade performance over time. What we did differently is create silicon inside a porous carbon matrix—a hard carbon, not graphite. We leave space for the silicon to expand. Our material is a composite: about half carbon and half silicon by weight, and by volume, about a third each of carbon, silicon, and void space. This way, we get the power of silicon—five times the capacity of graphite—while maintaining good surface and connectivity from the carbon. It’s the best of both worlds with Group 14’s approach.

Jeff Dance: That’s awesome. Tell us more about EVs. There’s been a major trend toward EVs, with some backlash, but things are still moving forward. Is the idea that companies like Toyota are talking about doubling range because they’re relying on this technology for the future?

Rick Costantino: I can’t comment on specific customers, but there’s definitely a lot of good things coming. Silicon enables better range and faster charging, and that’s been demonstrated repeatedly. Silicon is coming. Today, there are some batteries using other types of silicon materials, but the revolution has already started. It takes longer to get into automobiles because of strict requirements and longer development cycles, but it’s coming.

Jeff Dance: And clearly, longer range. I think the real tipping point is charging—not so much range anxiety, but charge anxiety. Once people can charge in 10 minutes, maybe five minutes, or even 90 seconds with some of our customers’ batteries, I envision a future where you could charge inductively while driving through a tunnel or toll booth.

Rick Costantino: Exactly. The technology is getting there, but the infrastructure needs to catch up to support these fast charging rates. The technological feasibility is happening now.

Jeff Dance: I like the idea of driving into a tunnel, grabbing an ice cream, and by the time I get through, I’m ready to go another couple hundred miles. That’s future thinking. It’s interesting to have the technology at play. As for the speed of innovation, you mentioned consumer electronics move faster, while the auto industry is slower due to regulations. Would you say a lot of this is also about the supply chain? Is it going to take time to shift the supply chain ecosystem?

Rick Costantino: That’s a great point, Jeff. I was listening to your last podcast about AI, and you made a comment about innovation being not just about novelty, but about value. That resonated with me and Group 14. Since our genesis, we’ve been very plugged into the supply chain, trying to understand the value. People always ask if we make batteries—I say no, that’s hard to do. We let the experts make batteries, and we enable them to make better batteries, which allows automakers to make better EVs. There’s also the upstream side—we need materials like silane gas to make silicon. We acquired the world’s most efficient silane technology in Germany. From the beginning, we’ve been plugged into upstream, downstream, and sidestream partners—those making other battery components. That’s the way to really understand value, and it’s been key to our success. Now it’s very popular to talk about the battery supply chain, but we’ve been focused on it from the start. We’ve weathered different political administrations and are now on the verge of having one plant in Korea and two in the U.S. coming online next year. The political winds will change, but people always need good batteries and materials.

Jeff Dance: Right. It seems like supply chain issues around materials have heightened the need for speed in what you’re doing. China is a big producer of graphite, and there have been concerns about access. Has that increased the urgency for your work?

Rick Costantino: Yes, absolutely. The need for a strong domestic supply chain is critical. That’s why at Group 14, we can build the full package—a silane plant, an anode plant, and partner with battery or auto companies anywhere in the world. Specifically in the U.S., every ton we make at our 2,000-ton scale plant is about 10 gigawatt-hours of battery energy—enough for about 100,000 EVs per plant. Every ton we make replaces five tons of imported graphite, giving us more domestic security. That’s very important for energy security.

Jeff Dance: We saw that transformation in the oil industry over the last decade, making us less dependent as a country. It sounds like we’re at the beginning of another transformation. If we’re at the tipping point, where do you see things evolving in the next five to ten years? It seems like a lot is already in motion.

Rick Costantino: I think the tipping point is here. I envision the electrification of everything—batteries in your clothing, eyeglasses, and more. Many of these things are already happening, but there are so many more possibilities. Imagine soaking up energy from the sun all day and running everything on batteries at night. I’m continually amazed at what our customers are doing. When we started, I didn’t foresee AI as a big opportunity, but now it’s huge. Drones are another area where better batteries are critical—for carrying more payload and flying farther, which is important for military applications. In the future, having the best batteries will be as important as having the best fuel. We need to be at the top of the world in making batteries, and that starts with making the best battery materials.

Jeff Dance: Yes, it’s a different type of energy, and as we shift that way, it becomes critical infrastructure for innovation.

Rick Costantino: Exactly. You mentioned in your podcast the analogy of the printing press and the telephone. People were skeptical at first, but those were revolutionary in democratizing information. I think batteries are on a similar path.

Jeff Dance: Right.

Rick Costantino: Or the telephone—now we can reach out to anyone around the world almost instantly. With advanced batteries, we’ll have energy at our fingertips anywhere. That’s going to enable so many new things, and it’s hard to predict exactly where it will go. There are certainly some risks, but I think there’s a lot of good we can do with it. That’s our mission—to see it through and see where it leads. Being in our part of the chain, I’m not sure what will happen on the other end, but I know it’ll be exciting and probably something I don’t expect. I’m looking forward to seeing what happens. AI is a great example of how quickly things can move.

Jeff Dance: Technology definitely has a life of its own. We can’t really control it, but it has a lot of potential for good, even though there are always some bad actors and negative use cases. That’s a thesis I’d like to reiterate. From a specificity and flexibility perspective, what is it about this technology that makes it more flexible? Is it the smaller, lighter form factor, or is there something else that enables more innovation? You mentioned batteries in clothing—what’s driving that flexibility?

Rick Costantino: There are two pieces to that. The first is how you can use the material. When we were designing our battery material, we realized there’s a terawatt of battery production worldwide based on graphite. So, we made sure our material could be used in those existing factories. Otherwise, you’d be asking customers to build a new plant just for your material, which is a huge ask.

Jeff Dance: So it fits into the existing supply chain.

Rick Costantino: Exactly. Our material has a “drop-in” ability. It’s a black powder, and you can simply substitute it for graphite in the same hopper. You might need to tweak your process a bit, but fundamentally, you don’t have to change your plant. You can also decide how much graphite you want to displace. Some customers start with a modest improvement—maybe improving their battery by 20%. They don’t want to double it right away; they want to roll out improvements gradually.

Jeff Dance: It reminds me of someone, but keep going.

Rick Costantino: I can’t name names, but the point is you can use our material at 10% or 20% and still have 80% or 90% graphite, and you’ll get a noticeable performance boost with minimal changes. Or you can use 50% or even 100% of our material for a huge boost, which takes more optimization, but not new equipment—just some adjustments to the battery formulation. You’re still using the same scaled equipment. With new gigafactories popping up all over the world, being able to tap into those existing plants is huge, and it’s always been part of our business model. That’s the first piece of flexibility.

Jeff Dance: Mm-hmm.

Rick Costantino: The second piece is how our material can incorporate into different types of batteries or chemistries. For example, there are different cathodes—some are high-energy NMC types, others are more common but inexpensive LFP types. Many auto companies are going that way. Our material works with either, and we’ve presented data on both. It also works in different battery form factors—pouch, cylindrical, prismatic. So, having a material that works in existing machinery and with different chemistries is really important. That allows for a “Cambrian explosion” of new applications.

Jeff Dance: That’s awesome. It’s clear you’re an ingredient in everyone else’s innovations. That’s exciting and brings up the idea of technology convergence. Often, we see big leaps when technologies converge—this plus that creates something new. What else do you see converging that’s going to change the state of batteries in the future? We hear claims from companies like Toyota about going from 300 to 700 miles of range—what else is converging that will help us leap forward?

Rick Costantino: My vision is that, although it will take a while, we’ll eventually have digital twins for materials and processes. Imagine having a digital twin of our material, and our battery customer has a digital twin of their battery-making process. Instead of spending months or years on physical trials, we could simulate everything and know what will work. Extend that to the auto level, and you can predict range improvements instantly. If we could tweak our material and instantly see the impact down the chain, with digital twins interacting, that would be the ultimate integration. There are challenges—like intellectual property—but that’s the holy grail of innovation. We’re seeing early bits and pieces of this already.

Jeff Dance: So, having a digital twin would let you innovate faster. I assume AI could play a role in optimizing and testing, running many scenarios in parallel. When you talk about different recipes, are you talking about converging silicon with sodium-ion, lithium metal, and other chemistries to find the best combinations for each innovation?

Rick Costantino: Exactly. For example, silicon works great in solid-state batteries. Companies like Solid Power have talked about using silicon. True solid-state with a lithium metal anode is different and a tough challenge, but silicon is compatible with many other chemistries. Sodium-ion is a bit different and may not be compatible with silicon, but there are many chemistries that will converge. Solid-state and silicon is already happening, and cathode innovation is moving quickly, too. The anode used to be the weakest link, but now that we’ve boosted it, the pressure is on the cathode side. It’s a positive feedback loop of increasing performance.

Jeff Dance: That’s great. With your technology, are we at the point where, in a few years, I’ll be able to charge my Cybertruck in 10 minutes? Does this technology enable that future?

Rick Costantino: I hope that in 10 years, you’ll be able to charge it in a minute or even less—single-digit minutes. The infrastructure needs to catch up, and we need to safely handle the heat and other challenges, but I think it’s possible. If we invest in infrastructure, the technology is already there or getting there.

Jeff Dance: Maybe one of Elon’s boring tunnels—he might go for that!

Rick Costantino: Could be! We’re already in hypercars like the McMurtry, which are ridiculously fast. I don’t know how drivers even hang onto the steering wheel! These electric race cars are wild. I always joke with my wife that I don’t want to get an electric car until our battery is in it. Of course, those hypercars cost millions, so I’ll have to wait for the mainstream models.

Jeff Dance: That’s awesome. What about other societal benefits from silicon battery adoption? You mentioned medical benefits—can you envision breakthroughs or benefits in that area?

Rick Costantino: The medical world is a great example where having reliable, smaller, and more energy-dense batteries is very important. I think we’ll see advances there. More broadly, the world’s demand for energy is rising exponentially, and we need to deliver it equitably. Batteries can help provide power and backup to underprivileged areas. Reducing dependence on fossil fuels is another big benefit. During the COVID pandemic, when everything slowed down, cities that had been polluted for generations suddenly had clean air. It was a sneak peek at a future where we rely on the sun by day and batteries by night, without pumping out smog or CO2. Even if I can play a tiny part in making that future possible, that’s a legacy I’d be proud of. That spirit drives our company’s vision.

Jeff Dance: I don’t think most people realize how much smog and pollution affect their health. Just living in a polluted city can reduce your lifespan by 5–10%. The idea that we could have transformational benefits is really appealing. How long have you been on this journey? I love the name Group 14 now that I understand it, but tell me more about your journey. There’s obviously been a lot of work to get to this tipping point.

Rick Costantino: My personal journey has been more of a random walk. I always knew I wanted to be a scientist, but I didn’t expect to become a battery scientist. I became a chemical engineer, focusing on nanoengineering. I worked in pharma for a decade, including on early GLP-1 drugs, which are now popular for weight loss. In 2009, I got a call from Rick Luby, now CEO of Group 14. He asked for help with freeze-drying for a battery material. I thought it was odd—freeze-drying is energy-intensive and expensive. I helped them solve that problem and invented a completely solvent-free process we call dryrolysis, which is much greener. Eventually, we spun out and got involved in silicon, changing the paradigm by thinking differently. I’m not a battery scientist by training, but not knowing what’s “supposed” to work was valuable—I was willing to try new things. That mindset was key, and I try to instill it in my team. Surrounding myself with great scientists and enabling them to think differently has been essential in cracking the silicon performance challenge. We’ve also relied on external expertise, like the DOE and our early investors, to get us moving in the right direction.

Jeff Dance: We’ve covered a lot of principles of innovation—trying things, having a beginner’s mindset, applying ideas from one industry to another, involving government support, and building both vertical and horizontal ecosystems. These are all key to transformation and innovation. It’s cool to see how you’ve employed these principles to reach this tipping point. Before we wrap up, I have two more questions. First, any other thoughts about the future of silicon batteries and the tipping point we’re at that we haven’t covered?

Rick Costantino: I think we’ve covered everything I intended. The vision of clean air is hard to top, but for me, it’s about what our customers can do. Every day, I hear from customers doing amazing things. I focus on my small piece of the puzzle—making the world’s best battery material—and let that propagate down the line.

Jeff Dance: That’s awesome. Last question: If you could collaborate with any existing or historical innovator, who would it be and why?

Rick Costantino: Thomas Edison, definitely. I have a similar mindset, and I was born in New Jersey—I’ve visited his lab, and it’s a fantastic place. His mentality of trying lots of things, as long as it’s safe, is inspiring. He said to have a great idea, you need to have a lot of ideas. Perseverance, excitement, trial and error—those are key. In a world focused on AI and prediction, there’s still a randomness and serendipity you can only get by working hands-on. Edison would be my scientific hero.

Jeff Dance: I thought the same when you talked about surrounding yourself with smart scientists and trying different things. There’s a “law of 100”—come up with 100 ideas and you’re bound to have a good one. I think Linus Pauling said that, but he probably learned it from Edison. I’ve loved chatting with you. I appreciate your passion and perspective, and how you’re bringing something good to the world. It takes smart innovators, a great team, and support to make it happen, and it sounds like you’re part of an exciting team for the future. Thank you for coming on the show and sharing your insights.

Rick Costantino: Thank you, Jeff. It’s been a pleasure chatting with you.