Article

Fresh Magazine Volume 1 Arrives

For the last several months, we’ve been hard at work creating a new way to experience all things Fresh, and we’re excited to share it with you.

Starting today, FRESH Magazine will be winding its way through the mail to our partners and friends.

Our theme for Volume 1 is Seeing, and you’ll find articles and essays showcasing everything from seeing the big picture in holistic product development to seeing in new dimensions, through augmented and virtual reality.

We’re especially excited to share case studies on Fresh’s work developing autonomous industrial vehicles with United Rentals and our own Telemus and Defeat BOCO projects. On the Fresh Culture side, we’ve got a meta-analysis of workplace personality quizzes as well as a tutorial on drawing great UI elements.

We didn’t go fully analog for this effort, though. FRESH Magazine comes paired with an augmented reality app (download it in the App Store or Android Play Store) so readers can experience the case studies and experiments through your device. If you don’t have a print copy, you can use this digital version to explore the content via our app:

The magazine was a great way to collaborate between the Portland, Oregon office and Bellevue headquarters, as the two teams came together under one banner. As the magazine went to print, we had the chance to visit our printing partner, Portland-based Premier Press, and reflect on what it meant for a digital product company to delve in a physical product.

As Marshall McLuhan pointed out in The Gutenberg Galaxy, the invention of moveable type subsequently the printing and bookmaking industry was a truly transformational moment in technology and human cultural development. Interchangeable parts, as an idea, started there, and so much about modern life depended on that concept, beginning with the press, and the creation of the concept of public opinion. The distribution of books and printed matter became a model for all product distribution, which, even in digital, endures to this day. Conceive and create; edit, iterate, and refine; print or manufacture or reproduce; commercialize, market, or otherwise sell; franchise it.

Every product goes on this cycle, but books were the first, most important things to be mass-made this way. So it’s always a treat to see how far this process has come and where it continues to go.

Here are a few photos and videos from the process, and a small virtual tour of Premier’s superb facility:

Premier is HUGE. 85k square feet for the press operations and 85k for fulfillment / distribution. It probably has the leading reputation among creative teams in Portland.

Premier does everything from digital to offset to letterpress to funky influencer kits. Here’s the foil station for foil embossing / debossing.

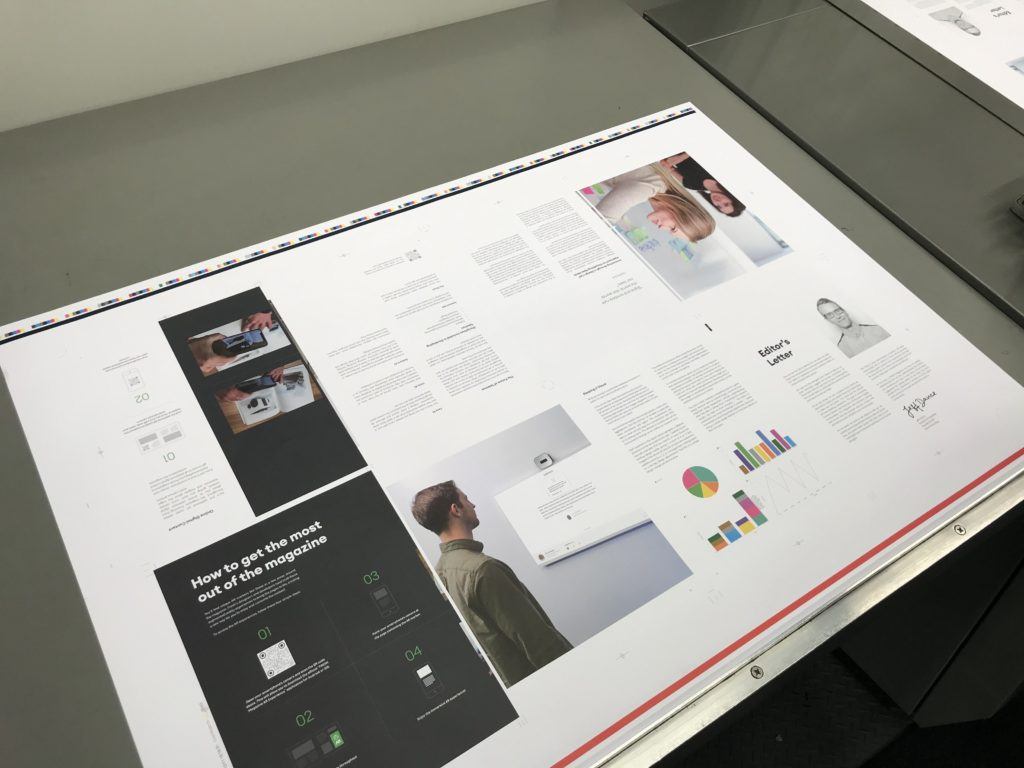

FRESH Magazine was printed on one of Premier’s Large Offset presses.

John, in the background, is the large offset operator running our magazine. The Komori printers here are state of the art.

Here John is using some page proofs to tweak paper stock feeding and color application / properties from the earlier proofs created with a smaller, slower Epson printer. You can see how long this printer is in this video. Once they get started they move FAST.

Also: the interfaces on these printers are FUNKY.

Here’s John doing more tweaking and dialing to get the colors right. Once he’s set these, we’ll roll with them throughout the rest of the inner book production process. We have the option to tweak each plate individually (I think we have like 12 total plates of 8 pages each) but our color schemes aren’t terribly complex so we’re leaving it up to John once we checked and signed off (literally) on the first plate.

And here’s the finished product!