Hardware

Save money, mitigate risk, and ensure acceptance by quickly turn product ideas into realistic proofs of concept for testing, validation, and iteration.

Fresh’s Rapid Prototyping Services and Capabilities

- Prototyping & Modeling

- Concept Modeling

- 3D Modeling

- Configuration

- 3D printing

- Fused Deposition Modeling (FDM)

- Stereolithography (SLA)

- Selective Laser Sintering (SLS)

- Direct Metal Laser Sintering (DMLS)

- Multi Jet Fusion (MJF)

- PolyJet

- CNC Machining

- Injection Molding

- Sheet Metal Fabrication

- Digital Engineering

- Simulation

- Assembly/Fit Testing

- Functional Testing

- Chemical Resistance

- Mechanical Properties

- Electrical Properties

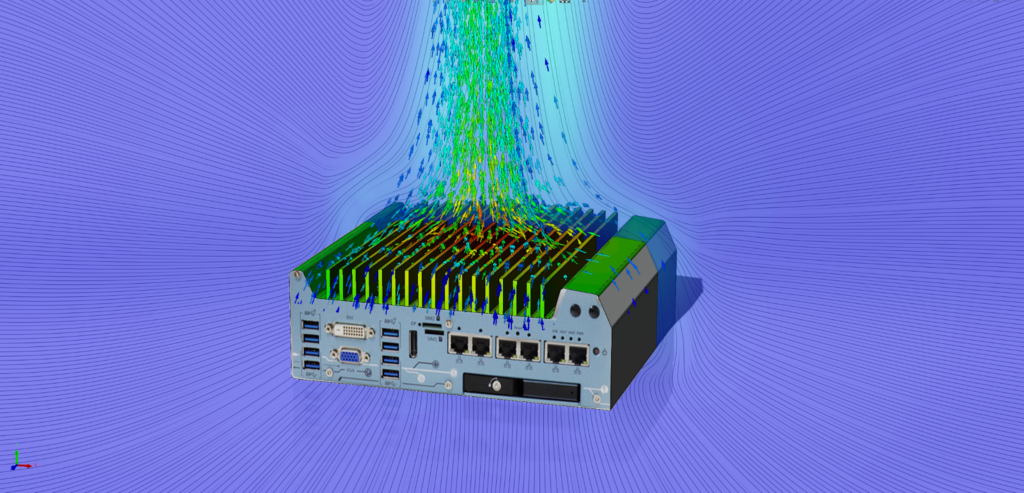

- Thermal Properties

- Optical Properties

- Life Testing

- Regulatory Testing

- Flammability Properties

- EMI/RFI Properties

- Food Rating

- Biocompatibility

- Computer-Aided Manufacturing (CAM)

Accelerate product development with rapid prototyping services

With rapid prototyping, Fresh’s engineers and industrial designers help clients turn concepts into real-world prototypes, conduct testing, and gather feedback. By investing in rapid prototyping to rapidly build and refine their design concepts, your organization can spot issues early and fine-tune effectively, reducing development time.

Our rapid prototyping services facilitate a key step in product development that allows your organization to go to market with confidence and quality.

Fast, cost-effective concept exploration

#1: Accelerate Development Timeline — By validating concepts up front, rapid prototyping dramatically reduces the time needed to turn concepts into physical, market-ready products

#2: Save Money — Our in-house engineers and industrial designers, equipped with best-in-class tools and techniques, enable you to get buy-in and sign-off while reducing waste

#3: Cost-Effectiveness — Get multiple product concepts at a fraction of the traditional cost before committing to full-scale production

#1: Iterative Design and Instant Changes

Quickly test, evaluate, and refine prototypes, to work toward a polished product before bringing production to scale

#2: Minimize Flaws

Testing conducted “early and often” with a realistic prototype helps identify and fix design flaws before they become expensive problems

#3: Verify and Validate

Physical models allow for more accurate evaluation of form, fit, function, and manufacturability, ensuring the final product meets requirements

Better Communication. Enhanced Innovation.

#1: Communicate Ideas Effectively — Tangible prototypes make it easier to convey design intent to stakeholders and team members, facilitating feedback and building consensus

#2: Enhanced Collaboration — Prototypes foster a shared understanding across departments, improving the efficiency and reducing the duration of product development workflows

#3: Explore Possibilities While Mitigating Risk — Rapid prototyping techniques encourage creativity by enabling low-risk exploration of new ideas and concepts

Rapid Prototyping Approaches

Proof-of-Concept Prototypes: These prototypes help teams validate ideas, challenge assumptions, and test a product’s viability before final assembly.

Looks-Like Prototypes: These prototypes give teams and stakeholders an idea of the look and interactivity of the end product.

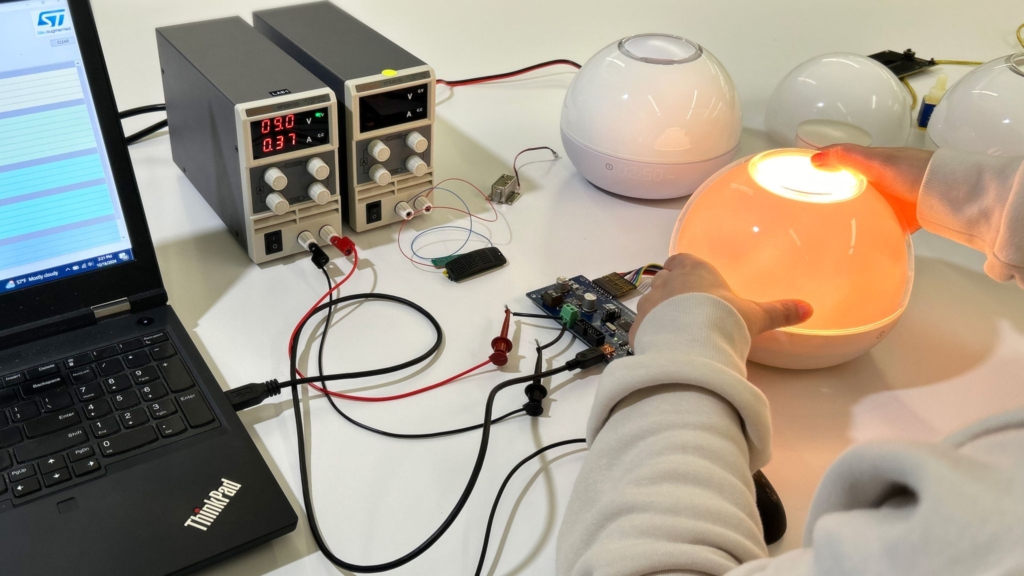

Works-Like Prototypes: Industrial designers and engineers follow steps and specialized techniques to test, iterate, and refine mechanical, electrical, and thermal systems.

Engineering Prototypes: Designers and engineers create a minimum viable version of the final commercial product, designed for manufacturability.

Validation Testing and Manufacturing: Create several small-batch runs, one-off custom solutions, and sub-assemblies for verification and validation.

Industries we work with

Fresh’s engineers bring the transformative power of rapid prototyping services to a diversity of industries. By quickly creating and refining prototypes, businesses across industries can drive innovation, enhance product quality, and accelerate time-to-market.