Article

Fresh is Now an ETL-Intertek Certified Fabricator

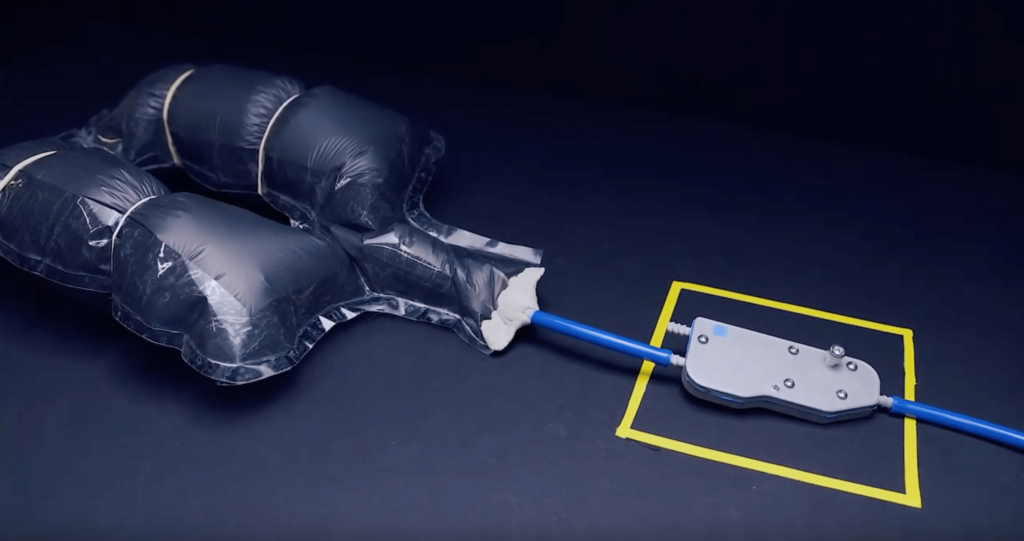

Rounding out an incredible 2022 at Fresh, our engineers hit a massive milestone. Due to rigorous collaboration and a unified vision for delivering value to our clients, we became an ETL-Intertek certified fabricator to mark control panels in North America.

Intertek’s website describes the historical roots of the mark and what it symbolizes:

“ETL was born into a culture of innovation. It was in Thomas Edison’s lighting laboratories where it all began, and to this day we still breathe the same air of innovation, safety and quality.”

They go on to describe the core value in a few succinct bullets, listed and summarized below:

- The ETL Mark is proof of product compliance meeting the requirements to become certified across North America.

- AHJs (Authorities Having Jurisdiction) and code officials across the US and Canada accept the ETL Listed Mark as proof of product compliance to established and published industry standards.

- Retail buyers recognize and accept it on sourced products, using the mark to find, vet, and select vendors.

- Consumers recognize it on purchased products as a mark of quality and safety.

Let’s dive into our journey to get ETL-Intertek certified and how the designation exemplifies our “client at the center” vision for service delivery.

The ETL-Intertek certification process: end-to-end engineering collaboration

The certification process was intricate, and it evolved several vital outputs:

- Compliance to UL STD 508a United States safety standards

- Compliance to CSA STD C22.2 #286 Canadian safety standards

- A comprehensive design submission

- Product descriptions & product photographs

- In-process quality control procedures during manufacturing

- Fabrication compliance checklist for engineering and quality control

- Tooling functionality checks of test and equipment calibration

The auditor assessment revealed zero nonconforming findings, a fantastic accomplishment on the part of our team and proof of the value, rigor, and process optimization we can deliver for clients.

How does ETL-Intertek certification benefit our clients and partners?

We’re now approved by nationally recognized testing laboratories, with proof of compliance with OSHA and North American safety standards.

This designation lets companies seeking ETL-authorized control panel manufacturers know that we guarantee that our fabrication complies with all safety regulations and is audited to the highest standards.

Additionally, Fresh is now authorized to inspect and repair competitors’ panel equipment.

For organizations needing to ship equipment internationally, a partner with ETL certification is a significant leg up, as regulators (customs agents, code inspectors, and other officials established outside of the United States or Canada) are familiar with ETL listed mark.

Let’s build the future—always with clients at the center.

We’re excited about the future and are thrilled about the new innovation opportunities our ETL certification enables for clients and partners within and outside the United States.

We’re also proud of our engineering team and the people who make it exceptional. Our ability to deliver value to clients and create value together will always hinge on the amazing people behind the work.

If you need services like manufacturing automation, product development, test automation, or anything connected to industrial design, a conversation with our team would be a great place to start so we can learn about your challenges and how our team can help.

We’re looking forward to the value we can create together in 2023 and beyond—let’s connect!